| two-dimensional space |

| The digital file produced from any CAD software package that creates a 2D drawing, which is the source for either printed-paper or a digital 2D formatted file (e.g., PDF). These files may or may not retain an associative link to their 3D CAD parent. |

| Technical information presented as a 2D drawing or other static document types that require manual human interpretation. |

| A 2-Dimensional Technical Data Package is based on 2 dimensional engineering drawings. 2D engineering drawings can be manually generated, or generated in a digital form. |

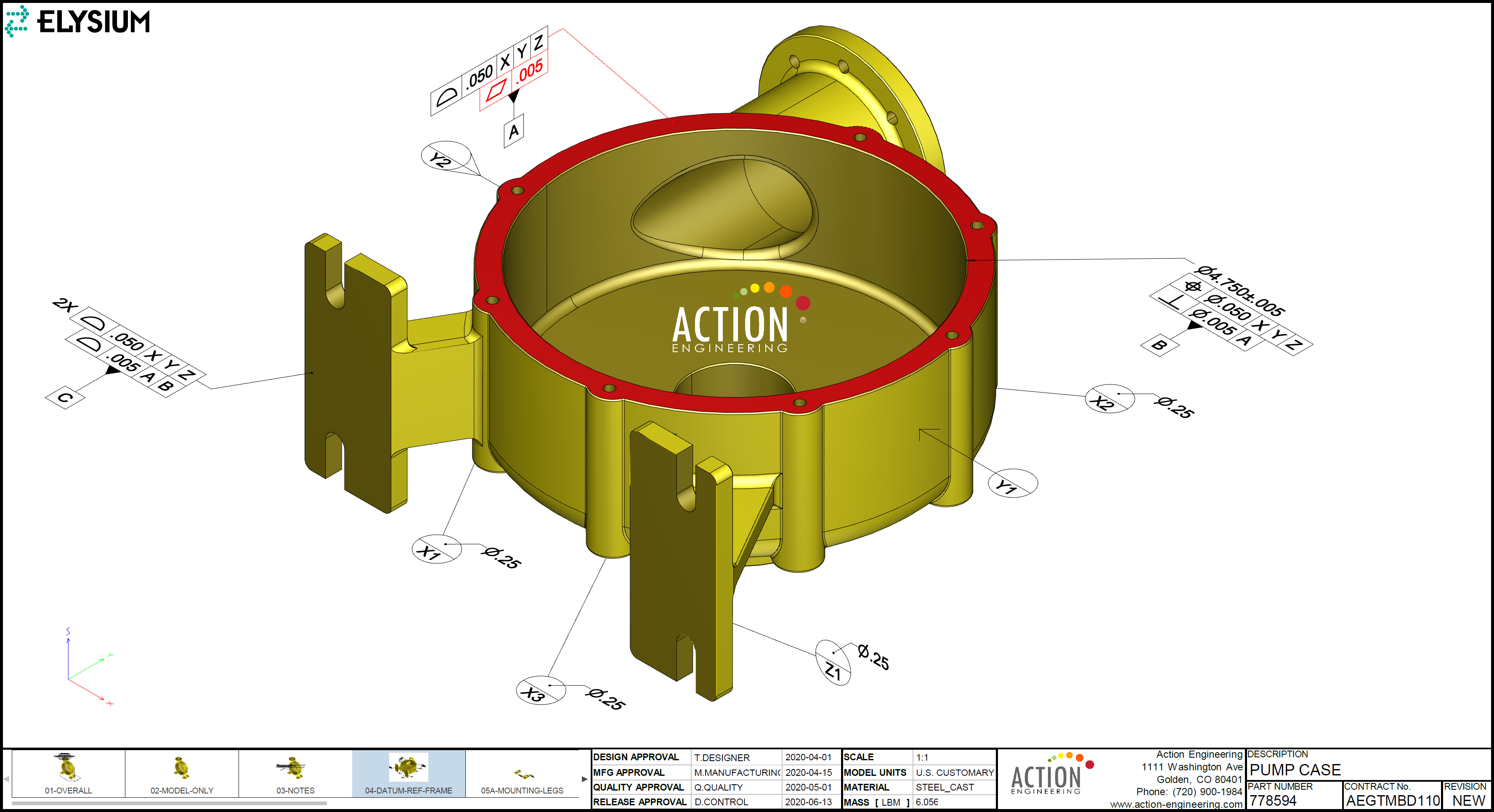

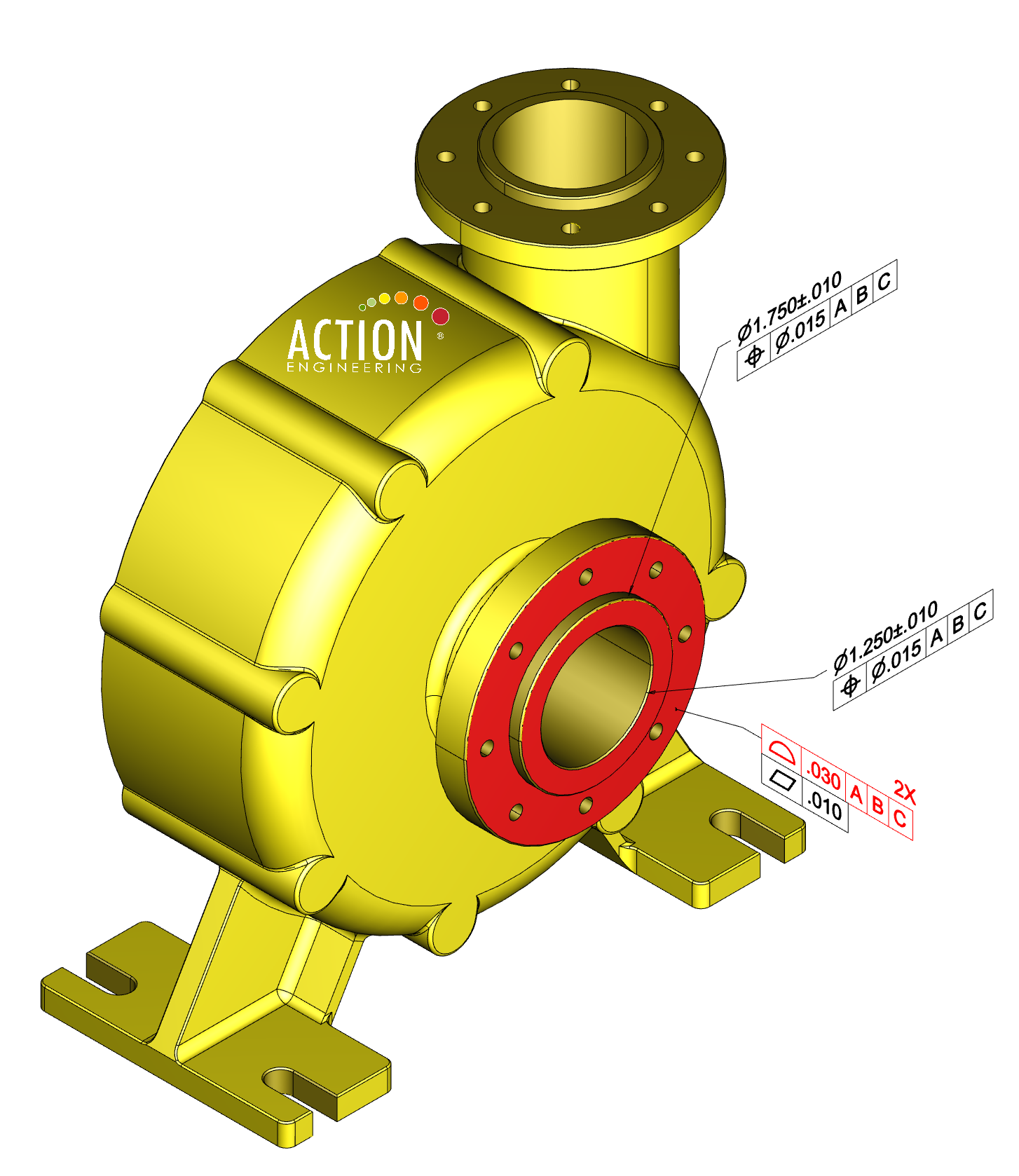

| A 3-dimensional viewable representation of an item provided in a widely available software format (e.g. ISO 32000-1 Portable Document Format (PDF)). This representation details the complete technical description of the required design configuration to include but not limited to geometry, topology, relationships, tolerances, attributes, metadata and other features necessary to define a component or assembly. |

| three-dimensional space |

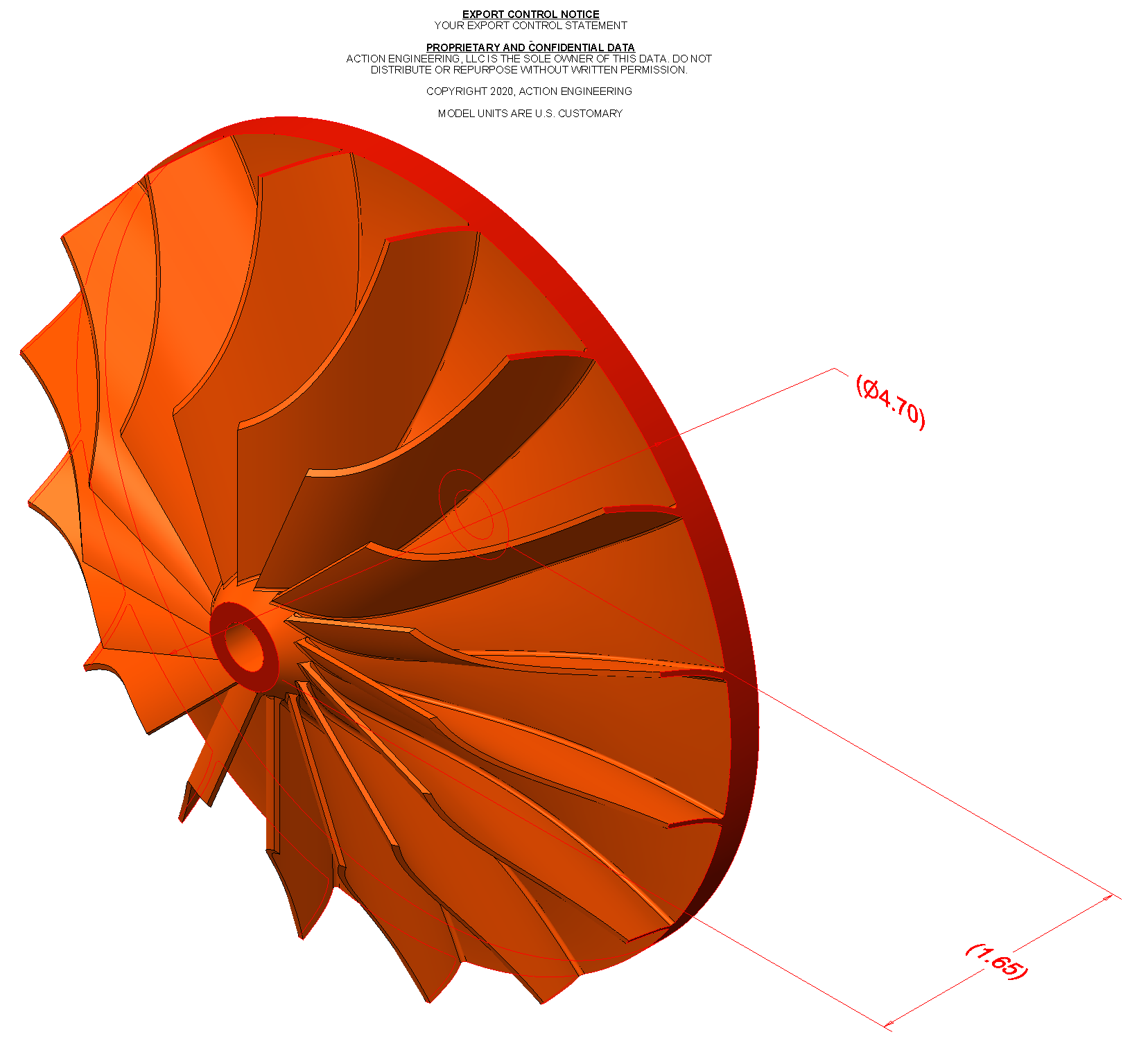

| The digital file(s) produced from any CAD software package that contains the 3D model of an object. It may or may not include Product and Manufacturing Information (PMI) annotations. |  |

| 3D Model of a physical item that is generated using drafting and design software. |

| Technical information presented as a dynamic 3D model that facilitates machine consumption opportunities while also displaying much of the 3D data for the human reviewer. |

| A term often used to describe a 3D PDF. It is a mathematically inaccurate term because a drawing is inherently 2D, and should not be described as 3D. |

| A three-dimensional derivative model that is interactive and is published in a ubiquitous format. |  |

| The capability of 3D data to seamlessly interchange between disparate systems. |  |

| 3D Model Based Definition | 3D MBD |

|

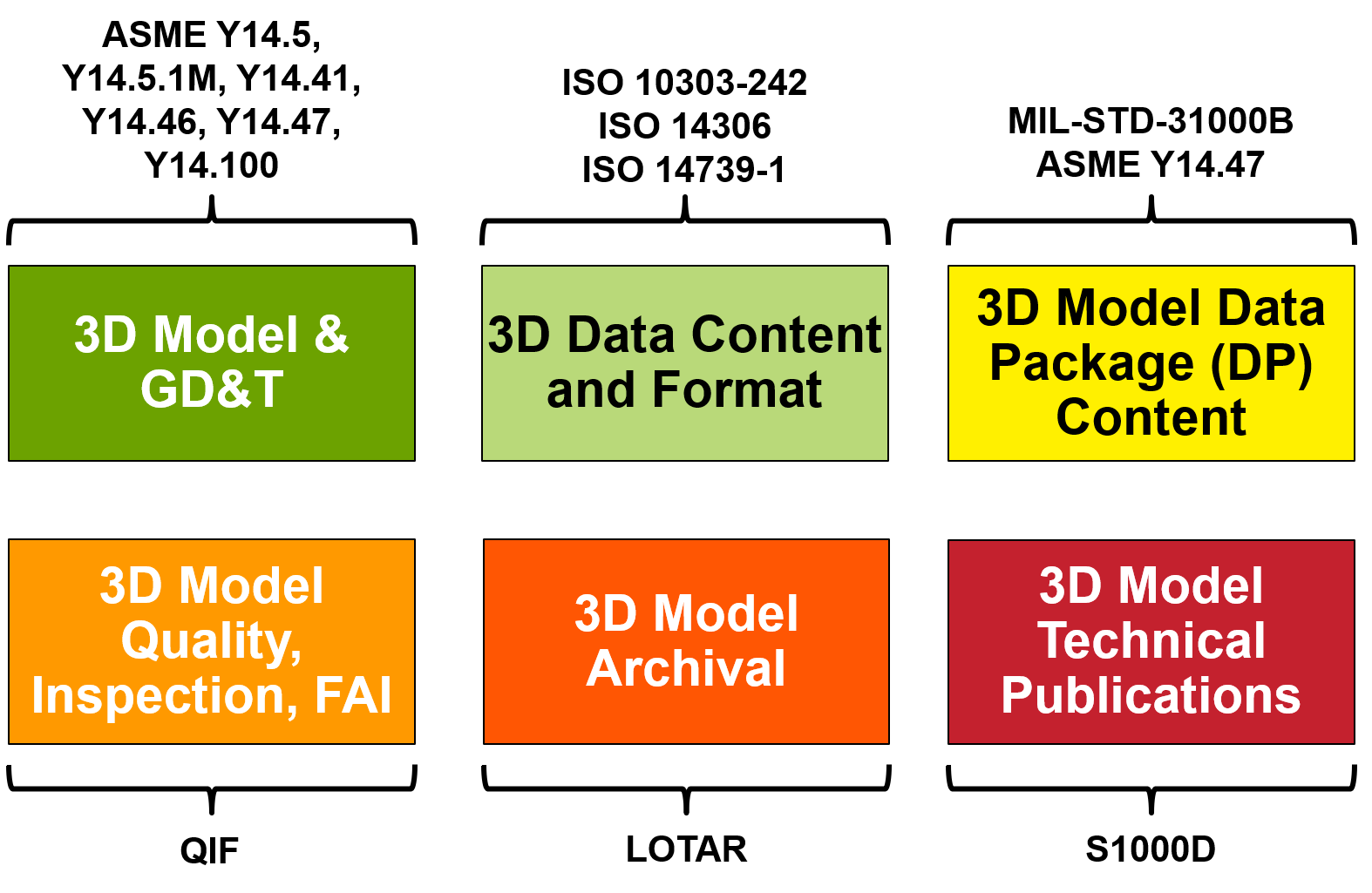

| Model Based Definition (MBD) is a set of concepts, processes, and tools that allow the creation of an annotated 3D product definition based on a 3D solid model. The MBD dataset includes all Engineering Intent requirements (including Process Specifications, Geometric Dimensioning & Tolerancing (GD&T), and other required information). Combined with product lifecycle management (PLM) attributes, a parts list, and general notes, this constitutes an authoritative, single source of master product definition data that does not include or depend upon traditional 2D drawings. The MBD dataset defines complete requirements for a product in its nominal condition as well as permissible limits of variation and other acceptance criteria, providing all the data needed to plan, fabricate, and validate an article of product hardware. |

| A PDF file that contains 3D geometry with associated text in a dynamic viewport. |

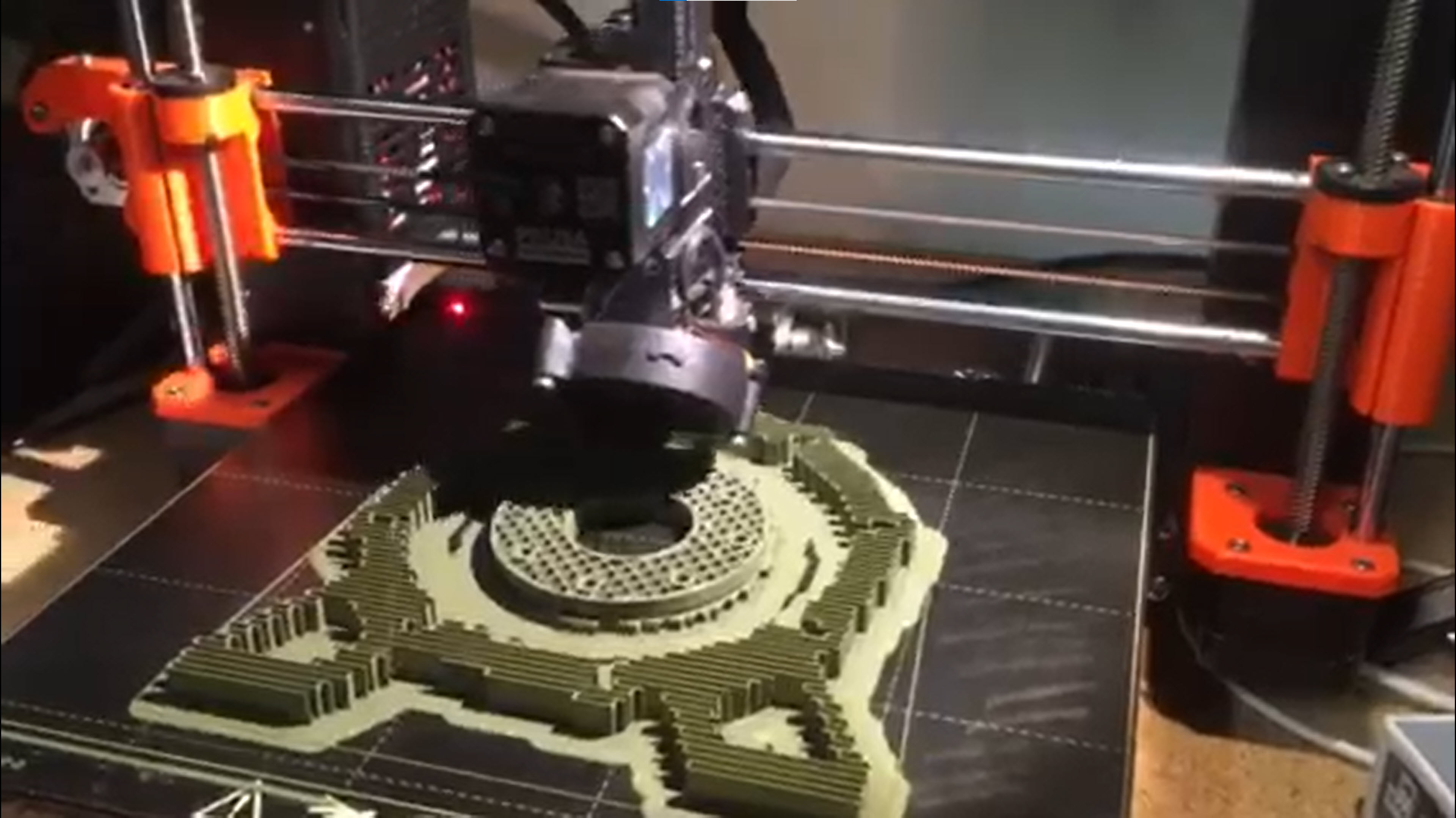

| A machine used for additive manufacturing. |

| A method of digitally acquiring and storing the shape and size of an object as a 3D data. |

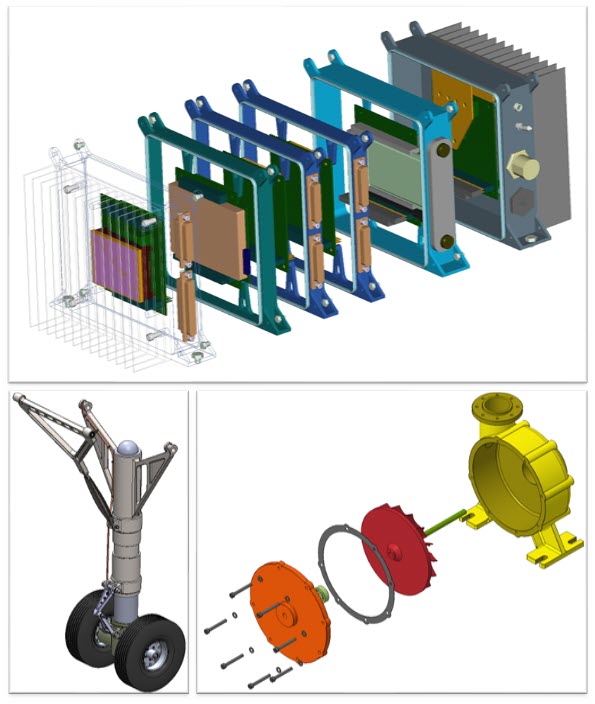

| A 3-Dimensional Technical Data Package based on computer based 3-dimensional models that are capable of generating, when required, 2D engineering drawings. Type 3D TDPs shall consist of one of the following type subsets: 3D digital models only, 3D digital models with associated 2D drawings. |

| The standard arrangement and organization of information within a 3Di viewable representation of an item. This includes such features as the size and arrangement of information blocks (e.g. title blocks), notes, lists, revision information, view states, restriction notices and the use of optional or supplemental blocks (see related term Drawing Format). |

|

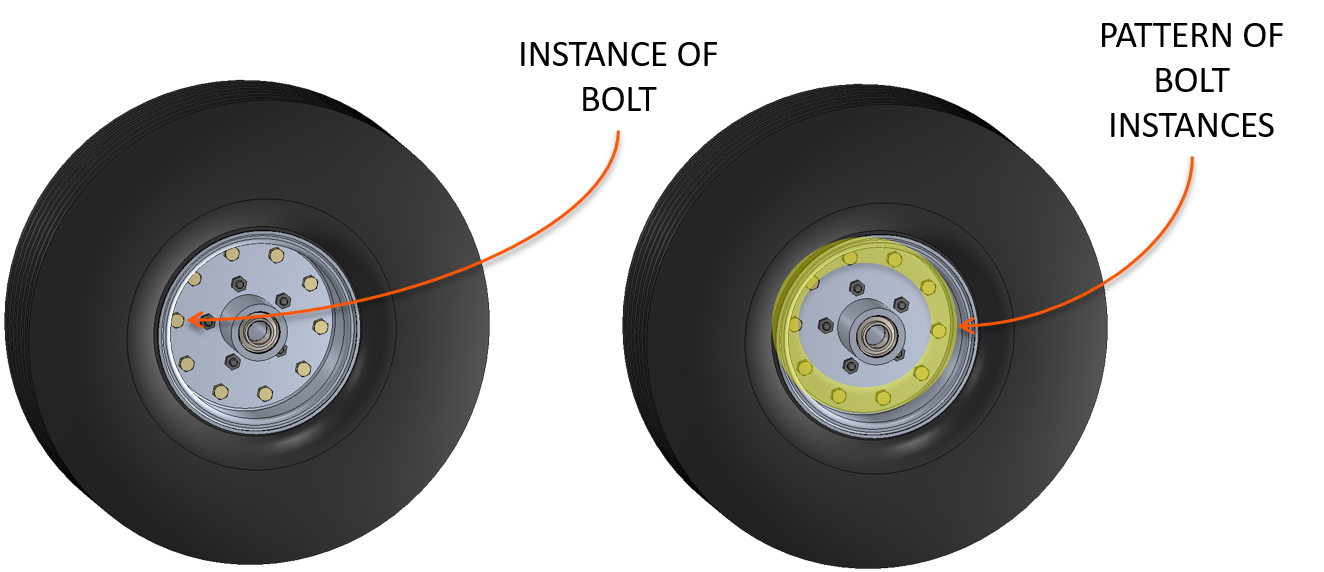

a physical instance of a component

Note 1 to entry: By analogy to a car, the design of a wheel is a part; the design of the wheel placed at the front right of the design of a car is a component; the front right wheel of a physical car is an actual component. |

| The actual value of any individual distance at any cross section of a feature of size. |

| A similar perfect feature(s) counterpart of smallest size that can be contracted about an external feature(s) or of largest size that can be expanded within an internal feature(s) so that it coincides with the surface(s) at the highest points. This envelope is on or outside the material. There are two types of AMEs, as described below. (a) related AME: a similar perfect feature(s) counterpart expanded within an internal feature(s) or contracted about an external feature(s) while constrained in orientation, in location, or in both orientation and location to the applicable datum(s). (b) unrelated AME: a similar perfectfeature(s) counterpart expanded within an internal feature(s) or contracted about an external feature(s), and not constrained to any datum(s). |

| A similar perfect feature(s) counterpart of largest size that can be expanded within an external feature(s) or of smallest size that can be contracted about an internal feature(s) so that it coincides with the surface(s) at the lowest points. This envelope is on or within the material. There are two types of actual minimum material envelopes, as described below. (a) related actual minimum material envelope: a similar perfect feature(s) counterpart contracted about an internal feature(s) or expanded within an external feature(s) while constrained in orientation, in location, or in both orientation and location to the applicable datum(s). (b) unrelated actual minimum material envelope: a similar perfect feature(s) counterpart contracted about an internal feature(s) or expanded within an external feature(s), and not constrained to any datum reference frame. |

| A process of joining materials to make objects from 3D data, usually layer upon layer, as opposed to subtractive manufacturing methodologies. |  |

| Any process of additive manufacturing (AM), such as those defined by ISO/ASTM 52900. |

| A number assigned to one or more interchangeable purchased items by a vendor item control drawing for administrative purposes. An administrative control number may also be assigned to an item defined by an envelope drawing. The number also serves as the PIN for specifying such items in a parts list. The administrative control number is assigned in addition to the item identification assigned by the original design activity. |

| A product definition data depicting the alteration of a nationally recognized standard or an item under the control of another design activity where the altered item meets specific design requirements and is no longer interchangeable with the original item. The altered item is re-identified with a new part number from the authoring design activity replacing the original part number. |

| A CAD model that contains additional product definition information required to perform product analysis (static, dynamic, thermal, etc.). Most likely contains mesh elements to make it a Finite Element Model (FEM) and may contain control software to predict the products behavior. This may or may not be a derivative of the parent 3D CAD model. |

| A structured and logical approach that serves as a foundation and starting point for conducting data analysis. |

| The condition of a line element, surface, center plane of feature, tangent plane, or feature axis at an implied or specified basic angle of any value from one or more datum planes or datum axes. |

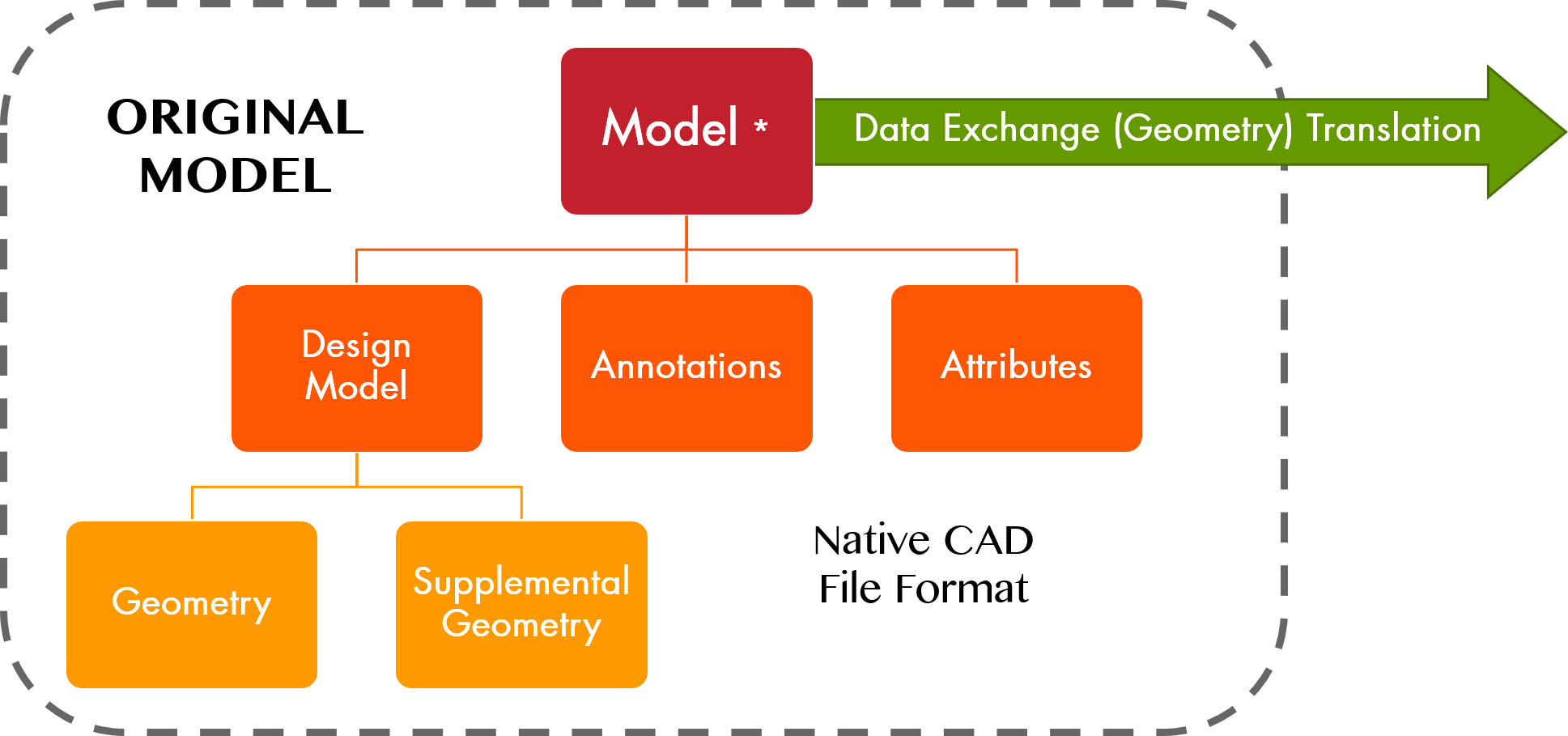

| A combination of model, annotation, and attributes that describe a product. |

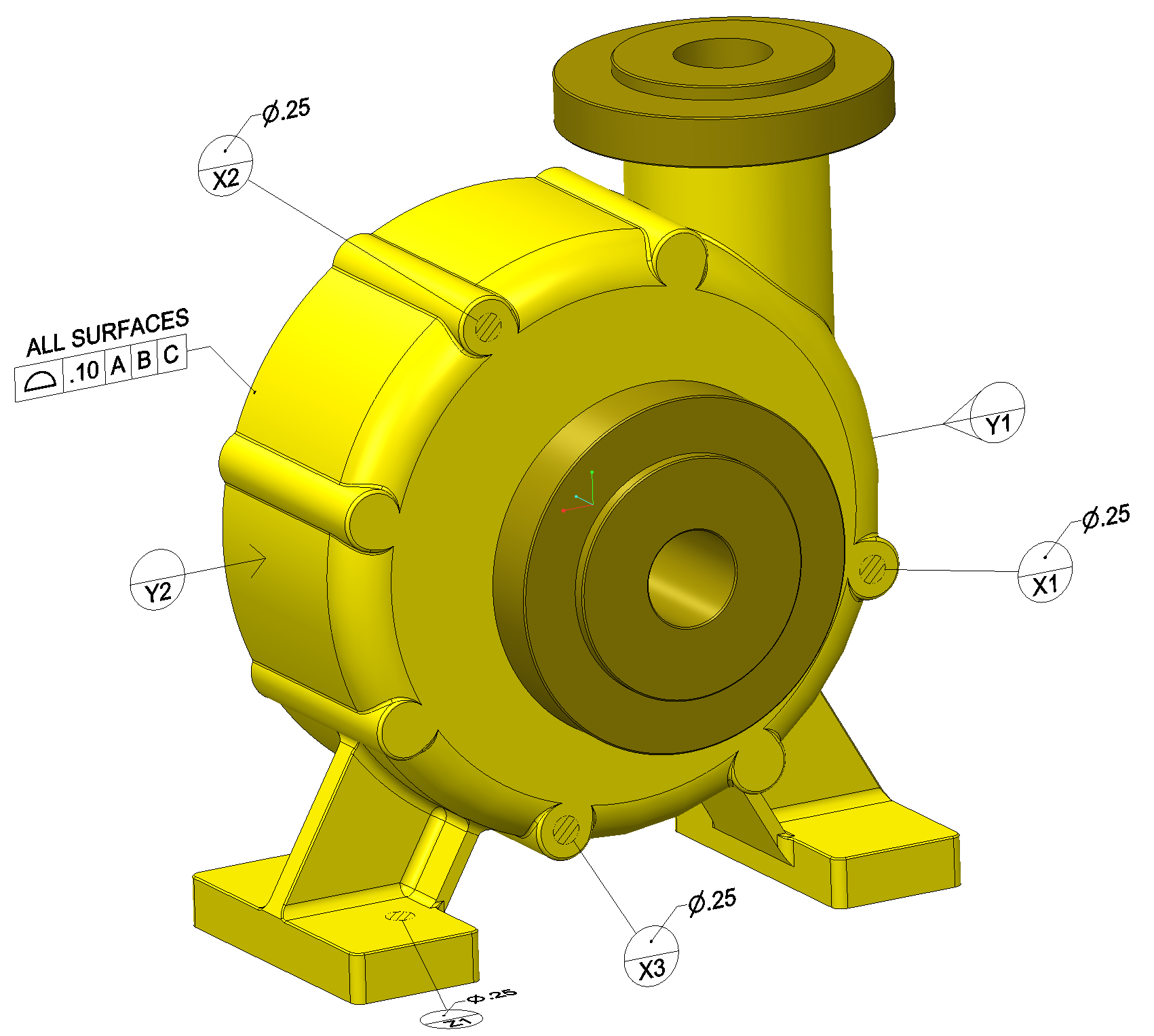

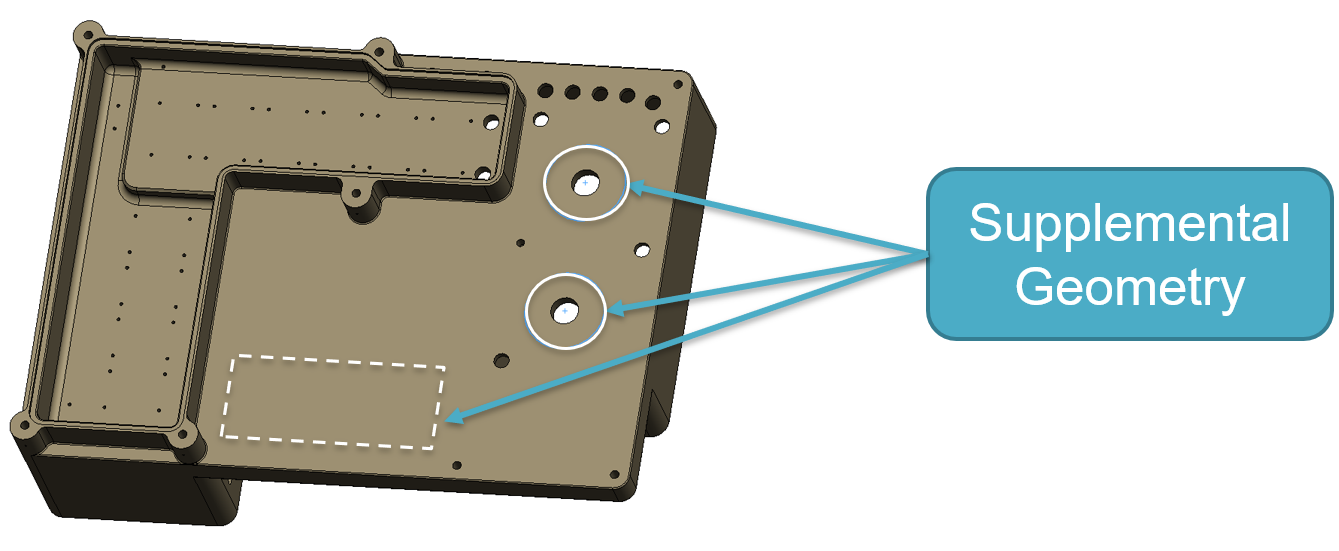

| Visible dimensions, tolerances, notes, text, or symbols. |  |

| An entity in the CAD model that contains an annotation, such as a dimension or a geometric tolerance. |

| An annotation orientation refers to the plane or the parallel plane in which the annotation lies, the viewing direction and the right direction or text rotation. One should maintain text orientation in a view that provides consistency for viewing. The orientation of the annotation plane should be maintained relative to the model geometry as the model is manipulated in 3D to comply with ASME Y14.41 section 5.2.3. |

| A conceptual plane containing annotation that either perpendicularly intersects, or is coincident with one or more surfaces of a feature. |

| The completeness level of the annotations and attributes of an annotated model that are used to define an item. |

| The structure of components, their relationships, and the principles and guidelines governing their design and evolution over time. |

| Facts, characteristics, and concepts that define the structure of a system and the interrelationships between its parts and its environment. The data is created in a manner suitable for communication, interpretation, or processing by humans or by automatic means. For complex systems, a framework of conventions, principles and practices is used for organizing and presenting the architecture data within a specific domain of application or community of stakeholders. |

| An accurately scaled, usually 1:1, pattern that is used to produce the production master |

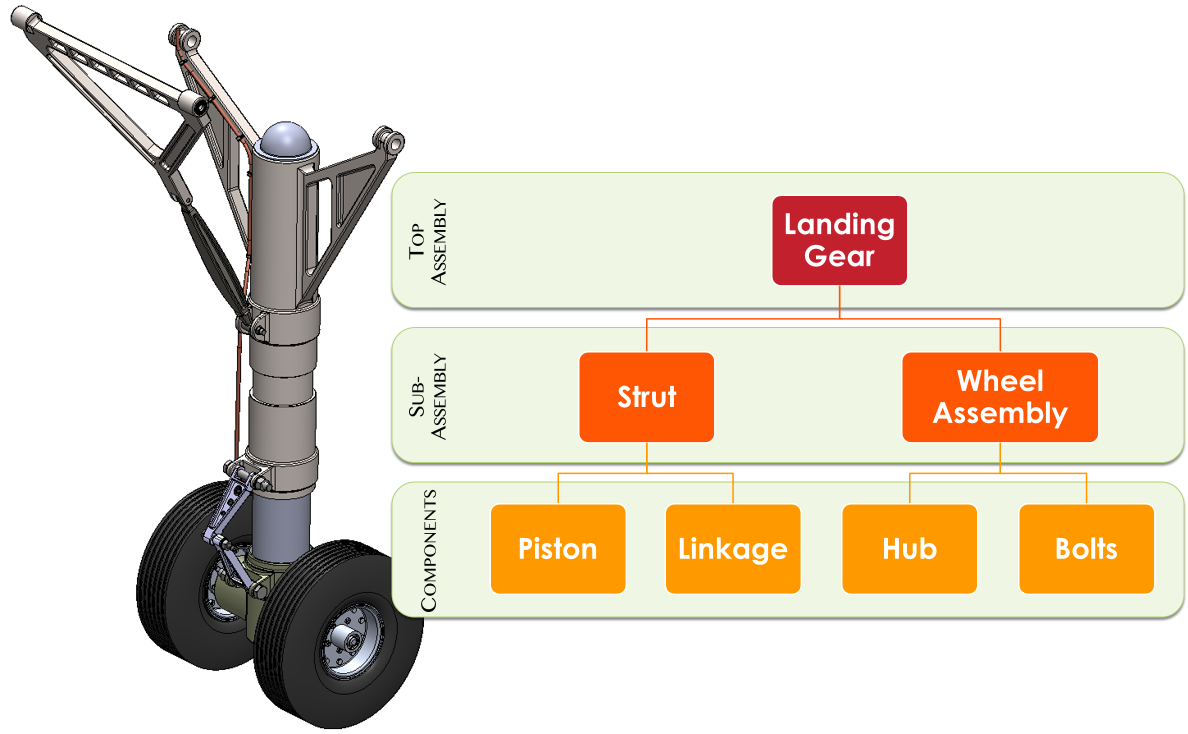

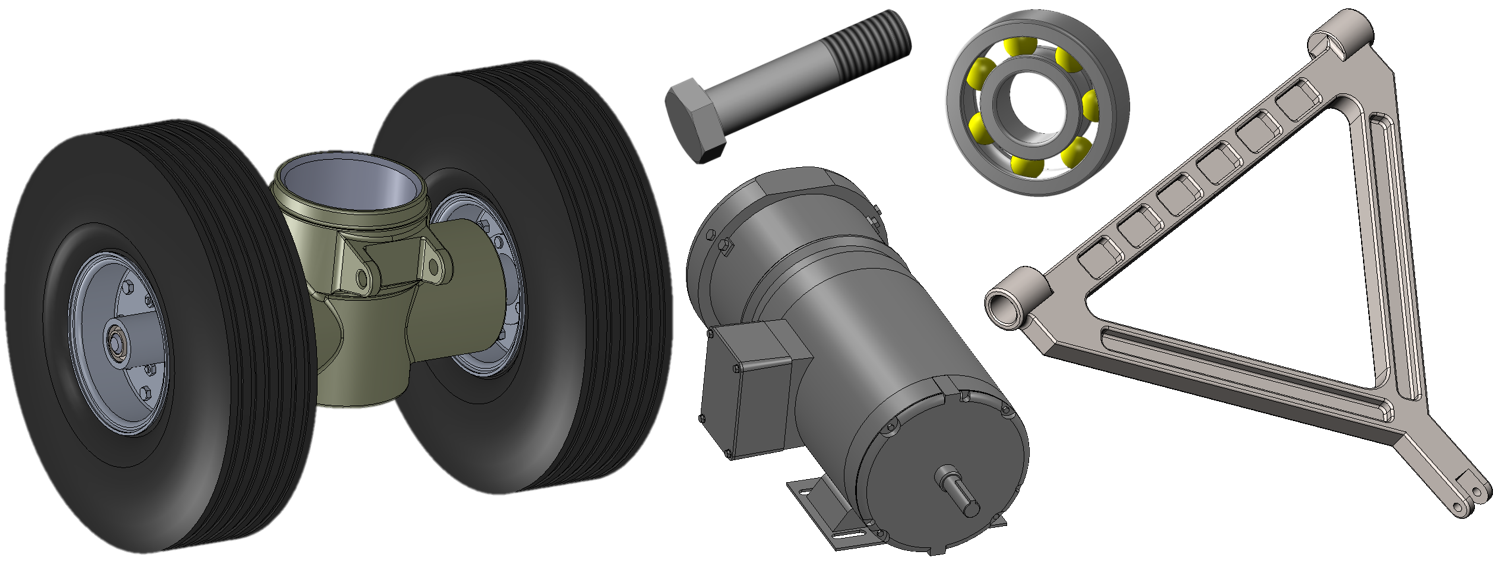

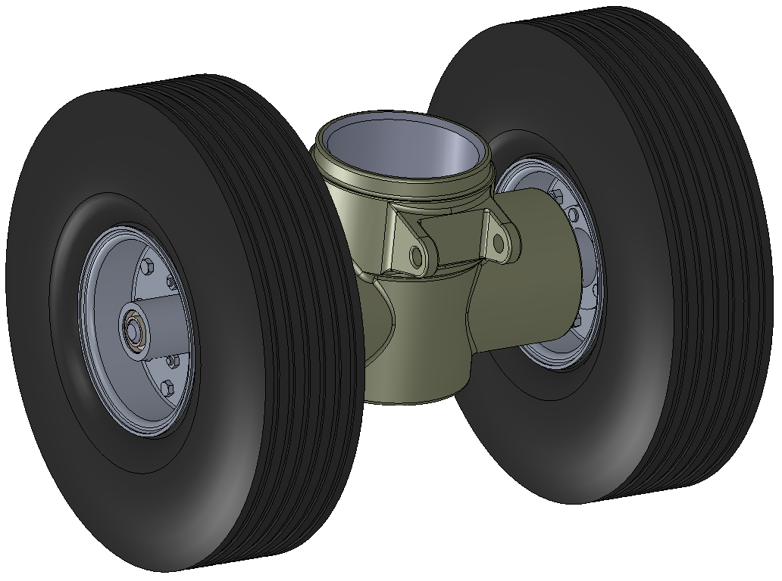

| A number of parts or combination thereof that are joined together to perform a specific function and subject to disassembly without degradation of any of the parts (e.g., power shovel-front, fan assembly, audio- frequency amplifier). NOTE: The distinction between an assembly and a subassembly is determined by individual application. An assembly in one instance may be a subassembly in another instance where it forms a portion of a higher assembly. |  |

| An associative relationship created from a component to assembly references (planes, axis, or coordinate system), or to another component in the assembly to define the component location and orientation within the assembly. |

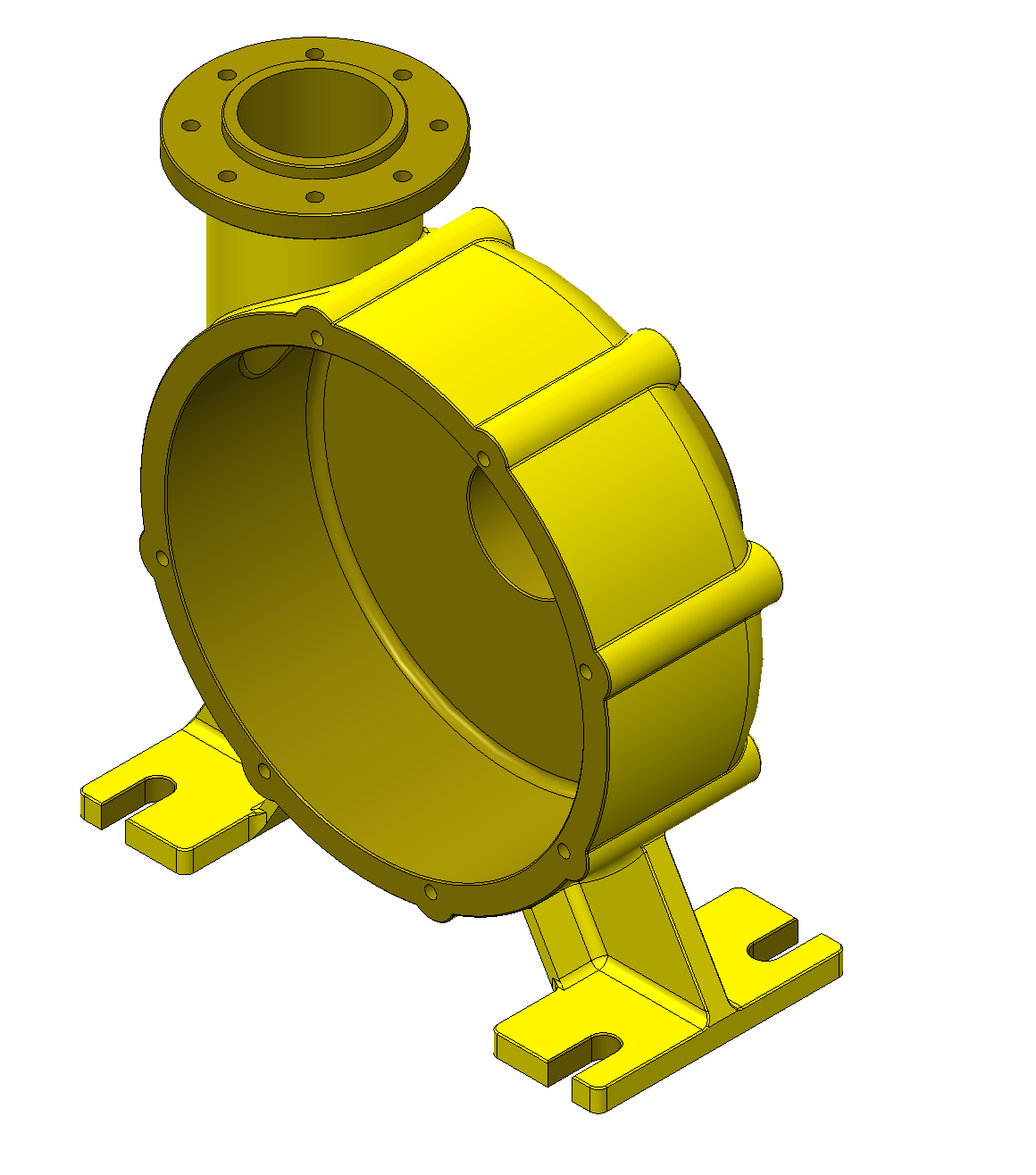

| A model in which the product described is an assembly of two or more items. |  |

|

a sequence with an id of the ids of components

Note 1 to entry: An assembly path shows where in an assembly design a specific instance of a part design or a subassembly design is located |

| Any document referenced on an engineering drawing that establishes some portion of the engineering requirements. |

| The portion of a product definition to which annotation pertains. |

| A user-defined set of related digital elements. |

| A tabulation of engineering information pertaining to an item depicted on an engineering drawing or by a set of drawings, e.g., application list, data list, index list, parts list, and wire list. |

| The established relationship between digital elements. |

| A dimension, tolerance, note, text, or symbol required to complete the product definition or feature of the product that is not visible but available upon interrogation of the model. |  |

| A result from a characteristic or property that is appraised only as to whether it does or does not conform to a given requirement (e.g., go/no-go, accept/reject, pass/fail). |

| An information provider that is sanctioned for a given lifecycle activity. |

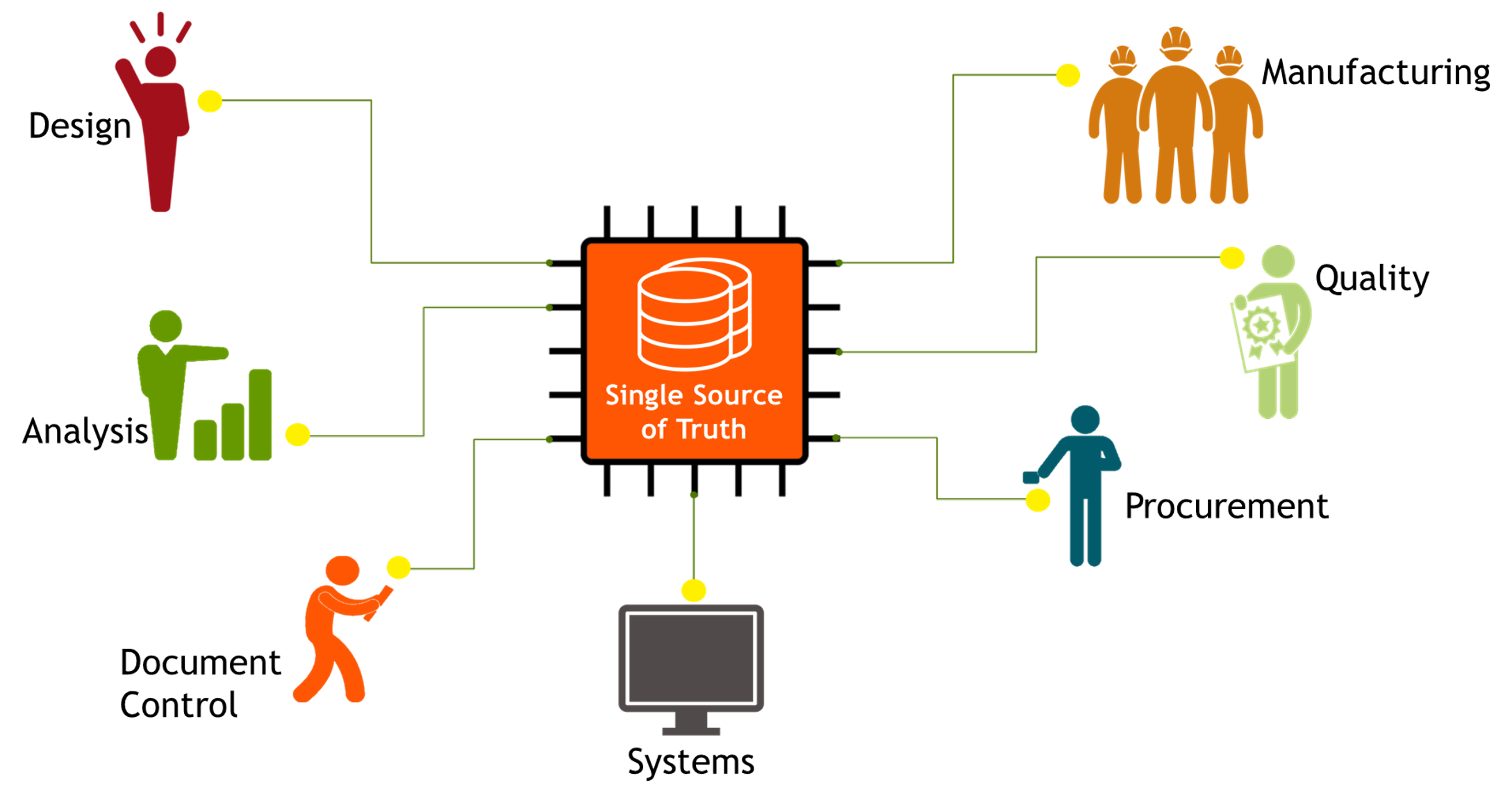

| The reference point for models and data across the system life cycle. The authoritative source of truth provides traceability as the system evolves, capturing historical knowledge and connecting configuration controlled versions of models and data. |

| A set of technical data which has been released and validated as adequate and complete for its intended purpose. |

| Approved by an authority for use in a lifecycle activity. |

| A digital representation of a thing approved by an authority for use in a lifecycle activity. |

| The average of several diametric measurements across a circular or cylindrical feature. |

| A model view that is primarily used to display annotations, where the surfaces of the model are not perpendicular to the viewing direction. |  |

| The model that a practitioner uses as the starting point for a given lifecycle activity. |

| A tolerance in which variation is permitted in both directions from the specified dimension or true profile. |

| a list of all the characteristics applied to a product. |

| A list of items, along with quantities and optional activity-specific information, needed to perform a particular lifecycle activity. |

| A surface subset within a part or on a part surface that is bounded by a set of connected or intersecting edges. |

| A volume subset within a part that is bounded by a set of connected or intersecting surfaces. |

| Orthogonally oriented minimum perimeter cuboid that can span the maximum extents of the points on the surface of a 3D part. |

| The direction in which layers are added in an additive manufacturing (AM) process to build a part. |

| The conditions in which a part is created. |

| Identification of the location of the build relative to the build platform. |

| Of a machine, base which provides a surface upon which the building of the part/s is started and supported throughout the build process. |

| Area where material is added, normally on the last deposited layer, which becomes the foundation upon which the next layer is formed. For the first layer, the build surface is often the build platform. |

| Total usable volume available in the machine for building parts. |

| Those constituents of an assembly or part (such as oil, wax, solder, cement, ink, damping fluid, grease, flux, welding rod, twine, or chain) that satisfy one or more of the following criteria: the quantity required cannot readily be predetermined; the physical nature of the material is such that it is not adaptable to pictorial representation; the finished size is obtainable through use of such tools as shears, pliers, or knives, without further machining operation; and the final configuration is such that it can be described in writing without the necessity of pictorial representation. |

| A digital file(s) produced from any CAD software package. Many file formats are possible. |

| CAD Bill of Materials | CAD BOM |

|

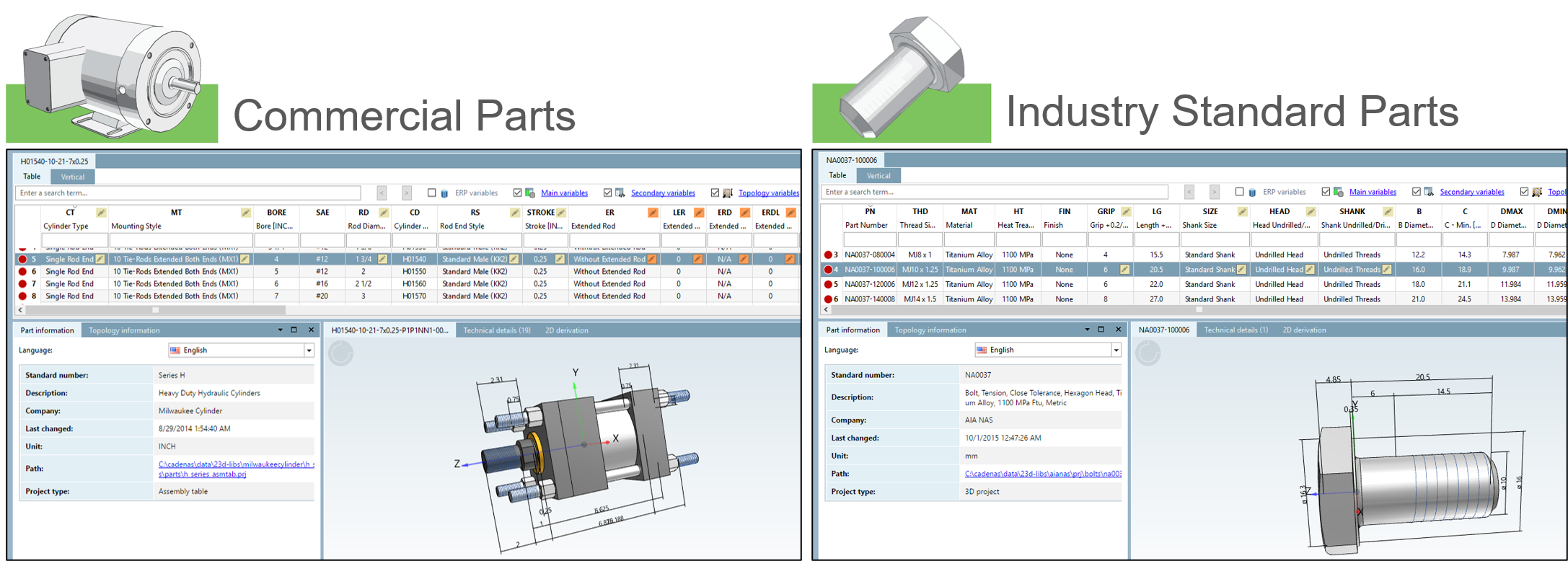

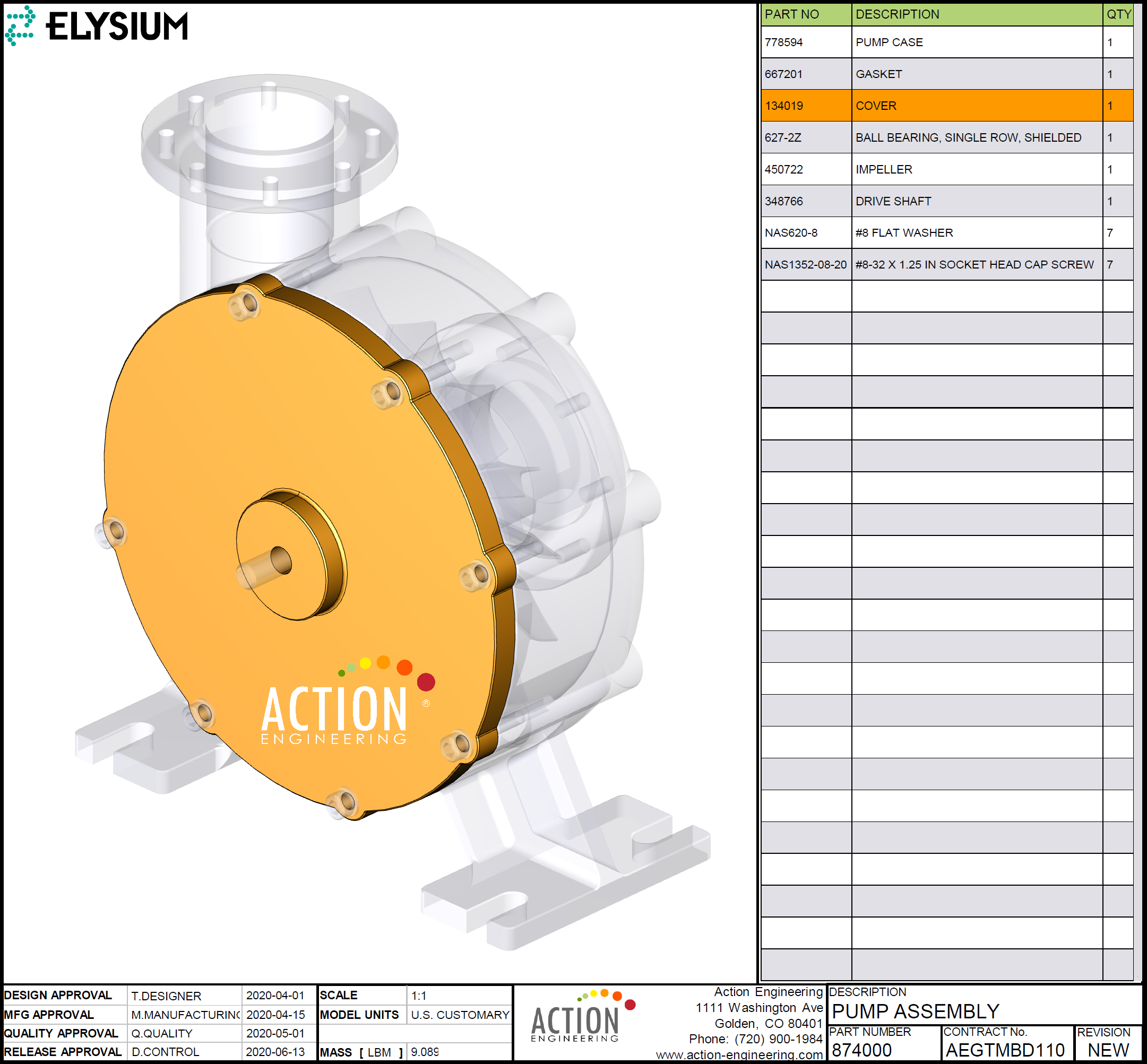

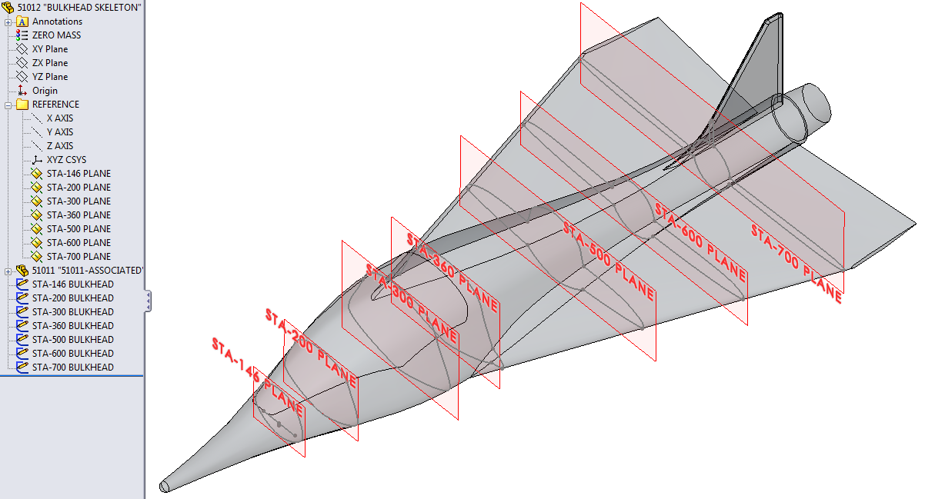

| The CAD bill of materials refers to the 3D CAD history tree of parts and components. It includes only what has been modeled; additional functional needs are captured in the following eBOM stage. |

| The hierarchical relationships among parts in a 3D assembly and among features in a feature-based part. Complex assemblies consist of subassemblies containing parts or possibly more subassemblies. Parts of feature-based CAD models consist of a base feature onto which additional features are applied. Features may themselves have dependent features. |

| Any part or subassembly commonly re-used within an organization’s products. |  |

| The center plane of the unrelated AME of a feature. |

| a control placed on an element of a feature such as its size, location or form, which may be a specification limit, a nominal with tolerance, a feature control frame, or some other numerical or non-numerical control. |

| An item of specialized supplemental information associated with a characteristic such as Criticality Classification, Product Requirement Associations, or Verification Plan Requirements. |

| A designator that labels a characteristic augmentation from its attributes. |

| A designator that labels a characteristic with its tag. |

| A human readable unique identifier. Characteristic IDs are assigned to tolerances within the Authoritative Technical Data to enable human readable tracking from native CAD data to derivative CAD data. The characteristic ID may also be consumed by downstream machine-readable equipment (e.g. inspection report generation). |

| a tolerance or specification applied to a feature or product that needs verification |

| A tag used for a characteristic. |

| A designator that labels a characteristic augmentation from its attributes. |

| A model that “trees” up into the next higher assembly/installation. |

| The condition in which each circular element of a surface is at zero variation relative to a datum axis or axis of rotation established from the datum reference frame. |

| The condition of a surface in which (a) for a feature other than a sphere, all points of each circumferential line created by the surface intersected by any plane perpendicular to the axis or spine (curved line) are equidistant from that axis or spine. (b) for a sphere, all points of the surface intersected by any plane passing through a common center are equidistant from that center. |

|

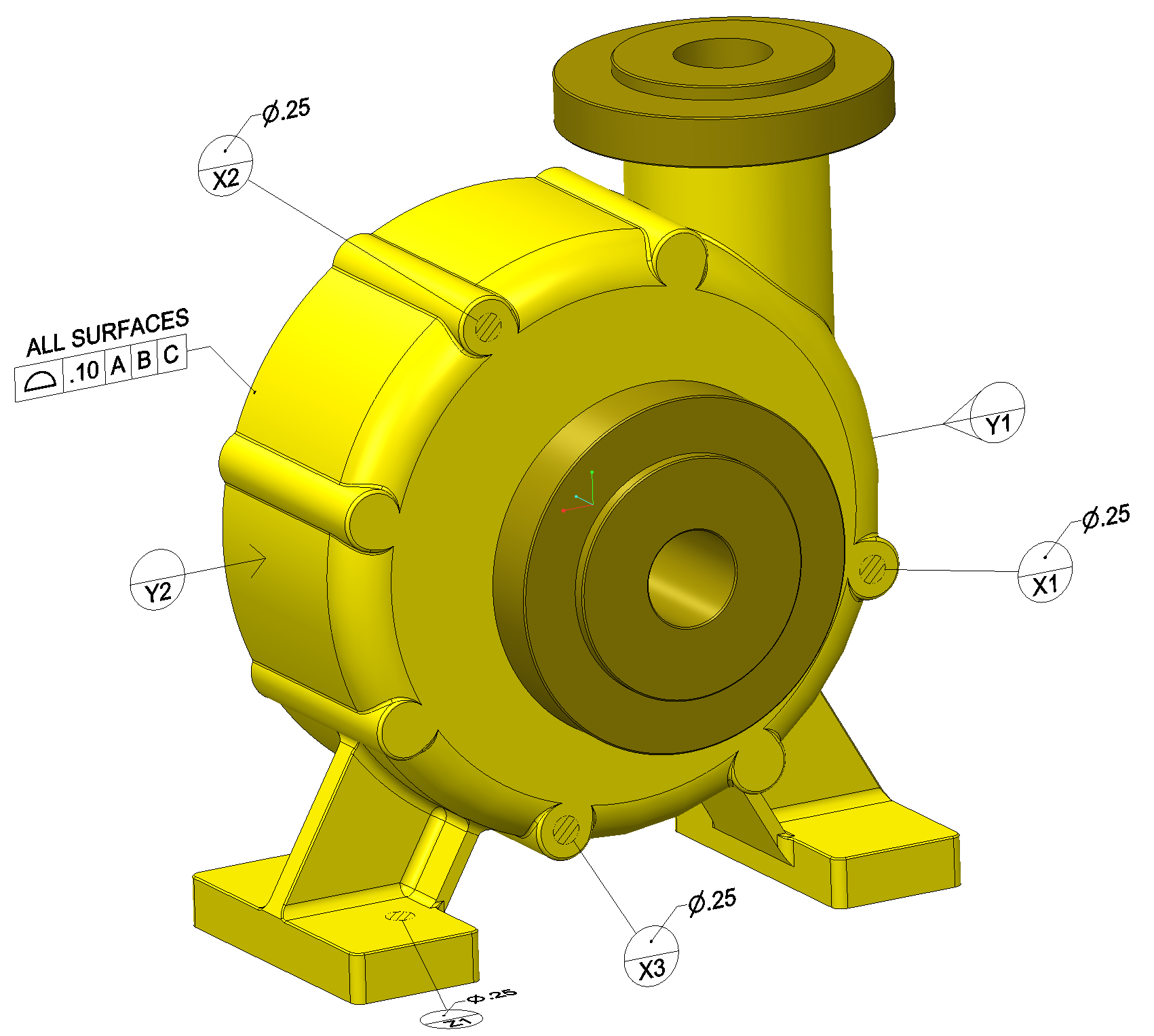

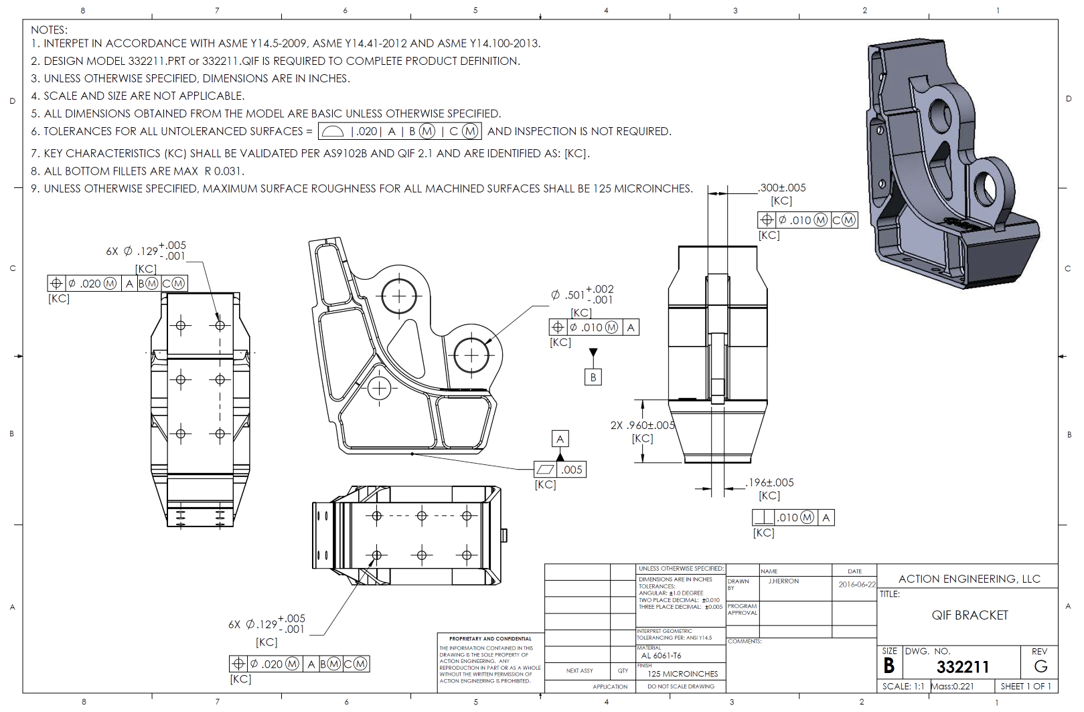

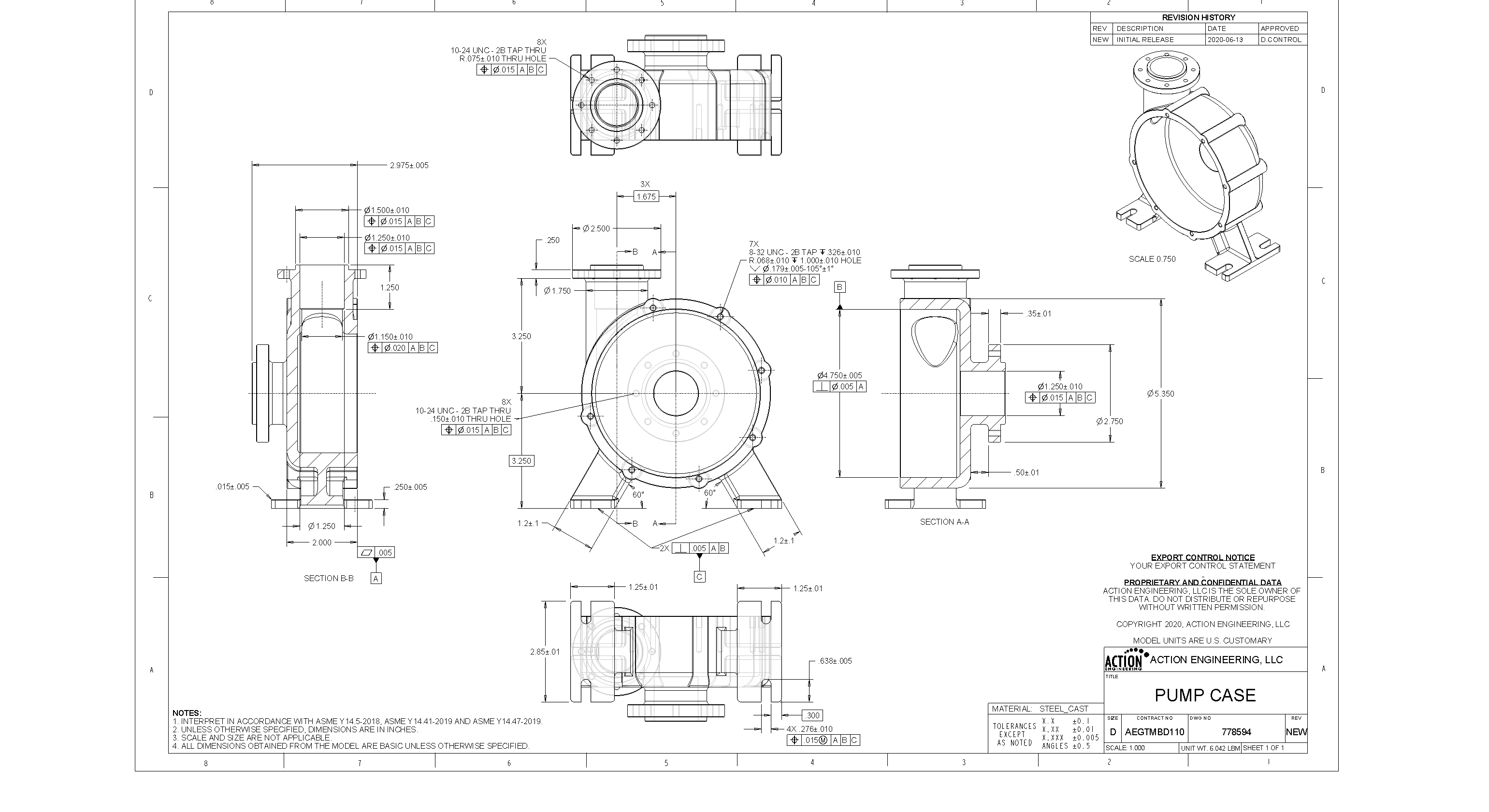

A designation assigned to product definition data that defines what product definition elements are included within the drawing graphic sheet, data set, or both.

NOTE: A drawing graphic sheet may be in either physical or electronic format. |

|

Drawing Graphic Sheet With Optional Data Set

Identifies that product definition elements are located on the drawing graphic sheet. |

|

Data Set With Model and Drawing Graphics Sheet

Identifies that product definition elements are located on a drawing graphic sheet. A computer is used as a tool to prepare the drawing graphics sheet and model. Product definition elements are located in the digital data and drawing graphic sheet.

|

|

Data Set With Model and Simplified Drawing Graphics Sheet

Identifies a model with a simplified drawing graphic sheet used to expedite communication of common part features and to define nongeometric part definitions. |

|

Data Set With Annotated Model and Drawing Graphics Sheet

Identifies that all product definition elements are located in both the digital data and drawing graphic sheet. |

|

Data Set With Annotated Model and No Drawing Graphic Sheet

Identifies that all product definition elements are located in the data set. No drawing graphic sheet exists.

|

| The condition in which the axis of the unrelated actual mating envelope (AME) or axis of the unrelated minimum material envelope, as applicable, of one or more surfaces of revolution is coincident with a datum axis or another feature axis. |

| Is prepared by a commercial design activity, in accordance with that activitys documentation standards and practices, to support the development and manufacture of a commercially developed product. |

| An existing product, material, component, subsystem, or system sold or traded to the general public during normal business operations at prices based on established catalog or market prices. |

| A five-character code that provides a unique activity identifier used by the government for activity identification. This method of activity identification has also been widely adopted by industry. |

| A document produced by a company that establishes engineering and technical limitations and applications for items, materials, processes, methods, designs, and engineering practices unique to that particular company. |

| A single surface of compound curvature or a collection of features. |

| Combines features that cannot easily be characterized by concise equations or algorithms (e.g., nonlinear, nonrepeating, random, etc.). |

| A part or subassembly model that is assembled into an assembly or subassembly model. |  |

| The use of computers to aid in the software engineering process. CASE tools may include the application of software tools to software design, requirements tracing, code production, testing, document generation, and other software engineering activities. Assemblers and compilers are CASE tools. |

| Use of computer software to control and manage manufacturing processes, such as automatically coordinated operations of conveyor systems, cutting and forming machines, and riveting and welding machines. |

| Engineering design data which describe the engineering concepts on which a proposed technology or design approach is based. |

| The collection of abstractions, assumptions, and descriptions of physical processes representing the behavior of the reality of interest from which the mathematical model or validation experiments can be constructed (adapted from ASME V&V 10). |

| An aggregation of hardware, software, or both, that is designated for configuration management and treated as a single entity in the configuration management process. The entity within a configuration satisfies an end use function and that can be uniquely identified at a given reference point. |

| precise, text definition of a characteristic required to be present in a conforming implementation |

| Two or more interrupted features designated with a CF symbol, indicating they are to be considered as a single feature. |

| Two or more regular features of size or an interrupted regular feature of size that is designated with a CF symbol, indicating they are to be considered as a single regular feature of size. |

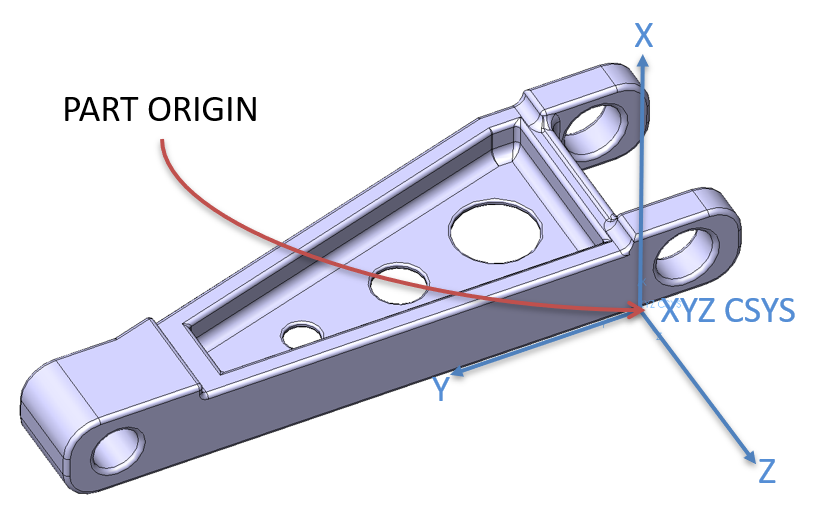

| A representation of a Cartesian coordinate system in a product definition data set. |  |

| The condition of two or more surfaces having all elements in one plane. |

| Any reproduction or duplication, in any media, of an original. |

| The essential minimum of data which are required to preserve the design intent for a given purpose. (NAS9300-003, 5.3.2.1) |

| Costed Bill of Materials | Costed BOM |

|

| Bill of materials which includes component costs for each component of the product. These include values for all costing items of a material, sales order or base planning object. |

| An unauthorized artifact (e.g., model) provided to a recipient. |

| Uses where failure of the item would result in one or more of the following conditions: (a) risk of personal injury or endangerment of life (b) loss of or damage to equipment (c) degradation of performance to a point that would jeopardize its capacity to fulfill its intended function. |

| A characteristic that analysis indicates is likely, if defective, to create or increase a hazard to human safety, or to result in failure of a system to perform a required function. |

| Those aspects of a systems capability, operational, or technical and other aspects that must be questioned before a systems overall suitability can be known. Critical issues are of primary importance to the decision authority in reaching a decision to allow the system to advance into the next phase of development. |

| A process that is the only known manufacturing method that will result in the production of an acceptable item. |

| A note of great importance that appears on a 3D model. |

| Any feature, such as tolerance, finish, material composition, manufacturing, assembly, or inspection process or product that, if nonconforming or missing, could cause the failure or malfunction of the critical safety item. |

| A part, assembly, installation, or production system with one or more critical safety characteristics that, if not conforming to the design data or quality requirements, would result in an unsafe condition. |

| Any fabrication, manufacturing, assembly, installation, maintenance, repair, or other process or procedure that implements a safety design feature or satisfies system safety requirements. |

| A relative measure of the consequences of a failure mode and its frequency of occurrence. |

| A characteristic augmentation that optionally designates a criticality. |

| A designator that labels a Criticality Classification. |

| A note of great importance that appears on a product definition. |

| The design activity currently responsible for the design of an item. This may be the original design activity or a design activity to which the design responsibility has been transferred. |

| A requirement that address a customer's expectations for the functionality, performance, and quality of a product being developed. |

| The condition of a surface of revolution in which all points of the surface are equidistant from a common axis. |

| Information represented in a formal manner suitable for communication, interpretation, or processing by human beings or computers. |

| The quantitative or qualitative characteristics of a data element. |

| storing, accessing, transferring, and archiving of data |

| A completed document that defines the data required of a contractor. The document specifically defines the data content, format, and intended use. (MIL-STD-963) |

| A collection of data treated as a single unit, such as a CAD model or file. |

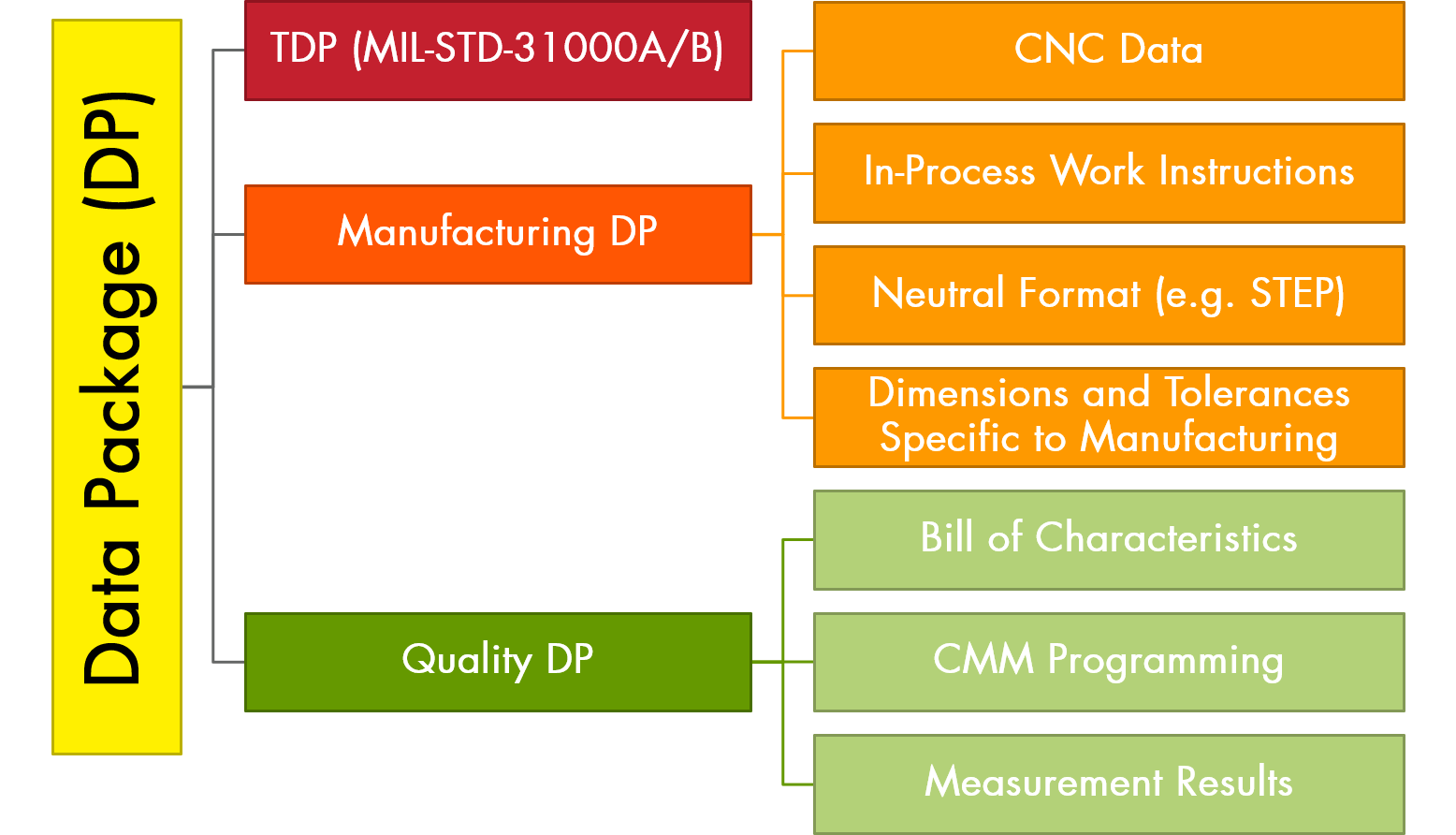

| Data Package | DP |

|

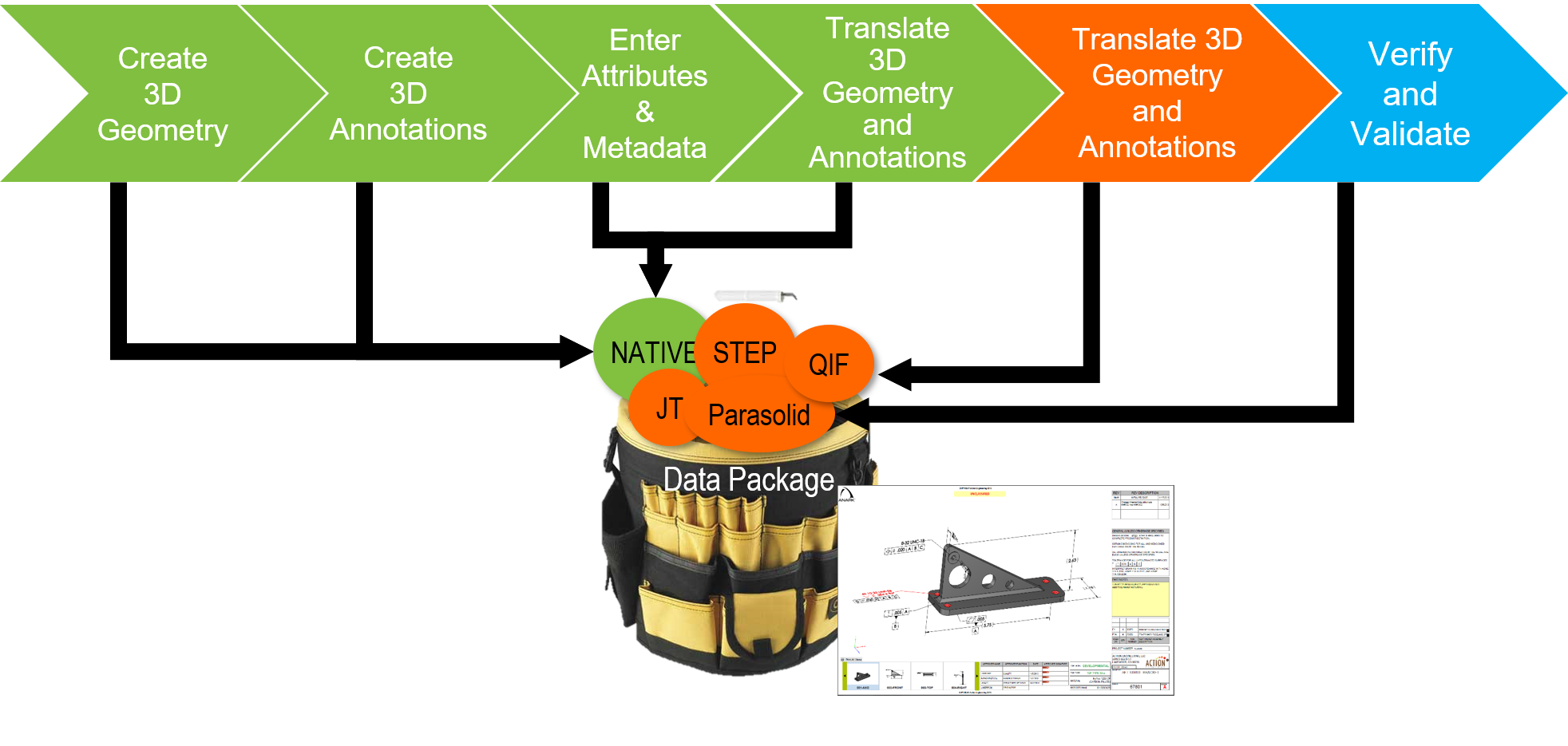

| A collection of 3D model geometry, annotations, attributes, and presentation states that includes a lightweight viewable file format that is intended for human readability. It may also contain derivate data and associated lists. |  |

| Silos enable logistical organization, development of expertise, and management of similar mindsets; paper-based practices result in insolated & disconnected 2D data, while model-based practices use connected 3D data with a well-maintained digital thread. |

| An identifiable collection of related data that serves a lifecycle activity. |

| A theoretically exact point, axis, line, plane, or combination thereof derived from the true geometric counterpart. |

| The center plane of a true geometric counterpart. |

| A feature that is identified with either a datum feature symbol or a datum target symbol(s). |

| The physical boundary used to establish a simulated datum from a specified datum feature. NOTE: For example, a gage, a fixture element, and digital data (such as machine tables, surface plates, a mandrel, or a mathematical simulation) are not true planes, but are of sufficient quality that the planes derived from them are used to establish simulated datums. Datum feature simulators are used as the physical embodiment of the true geometric counterparts during manufacturing and inspection. See ASME Y14.43. |

| The symbolic means of indicating a datum feature consists of an uppercase letter enclosed in a square or rectangular frame and a leader line extending from the frame to the feature, terminating with a triangle. |

| Three mutually perpendicular datum planes and three mutually perpendicular axes at the intersections of those planes. |

| The designated points, lines, or areas that are used in establishing a datum. |

| The symbolic means of indicating a datum target shall be a circle divided horizontally into halves. |  |

| Data duplicated or extracted from the original. A copy of a derivative is also a derivative. |

| A model created from a source model that may be transformed into a different format. |

| A set of technical data generated from master technical data. Typically derivative technical data is created to change its format to suit a different purpose. For example converting master, native format data to neutral or viewable data (e.g. STEP, PDF, etc.) so as to allow it to be read by a wider range of software applications. Changes to derivative technical data originate on the master technical dataset. |

| An imperfect (abstract) line formed by the center points of all cross sections of the feature. These cross sections are normal (perpendicular) to the axis of the unrelated AME. |

| An imperfect (abstract) plane formed by the center points of all line segments bounded by the feature. These line segments are normal (perpendicular) to the center plane of the unrelated AME. |

| An organization that has, or has had, responsibility for the design of an item. |

| The application of a unique identifier that distinguishes an activity or organization from another activity or organization. Examples of activity identification include activity name, activity name and address, or CAGE code. |

| The single source authority for the design model, annotations, and attributes. |

| Those dimensional, visual, functional, mechanical, and material features or properties, which describe and constitute the design of the article, as specified by drawing or DPD requirements. These characteristics can be measured, inspected, tested, or verified to determine conformance to the design requirements. Dimensional features include in-process locating features (e.g., target-machined or forged/cast dimensions on forgings and castings, weld/braze joint preparation necessary for acceptance of finished joint). Material features or properties may include processing variables and sequences, which are specified by the drawing or DPD (e.g., heat treat temperature, fluorescent penetrant class, ultrasonic scans, sequence of welding and heat treat). These provide assurance of intended characteristics that could not be otherwise defined. |

| A drawing or set of drawings and associated data that delineates the detailed engineering requirements of an end product necessary for the fabrication, assembly, inspection, and test of the item. |

| The portion of the data set that contains model geometry and supplemental geometry. |

| Qualitative and quantitative aspects of physical and functional characteristics of a component, device, product, or system that are input to its design process. Design parameters determine cost, design, and risk tradeoffs in the items development. |

| Design simulation helps manufacturers verify and validate the intended function and manufacturability of a product under development. |

| DFMA is an engineering methodology that focuses on simplifying the design of a product to improve ease of manufacture and efficiency of assembly. |

| A means to identify and set apart for a specific purpose. |

| Engineering design data which describe the physical and/or performance characteristics of a specific design approach to the extent necessary to permit the analytical evaluation of the ability of the design approach to meet specified requirements and enable the development, manufacture and testing of prototype or experimental material. |

| An artifact produced within, or generated from, the digital engineering ecosystem. These artifacts provide data for alternative views to visualize, communicate, and deliver data, information, and knowledge to stakeholders. |

| Geometric element, feature, group of features, annotation, associated group, or attribute that exists in a data set. |

| A label or name used to specify a unique digital element. |

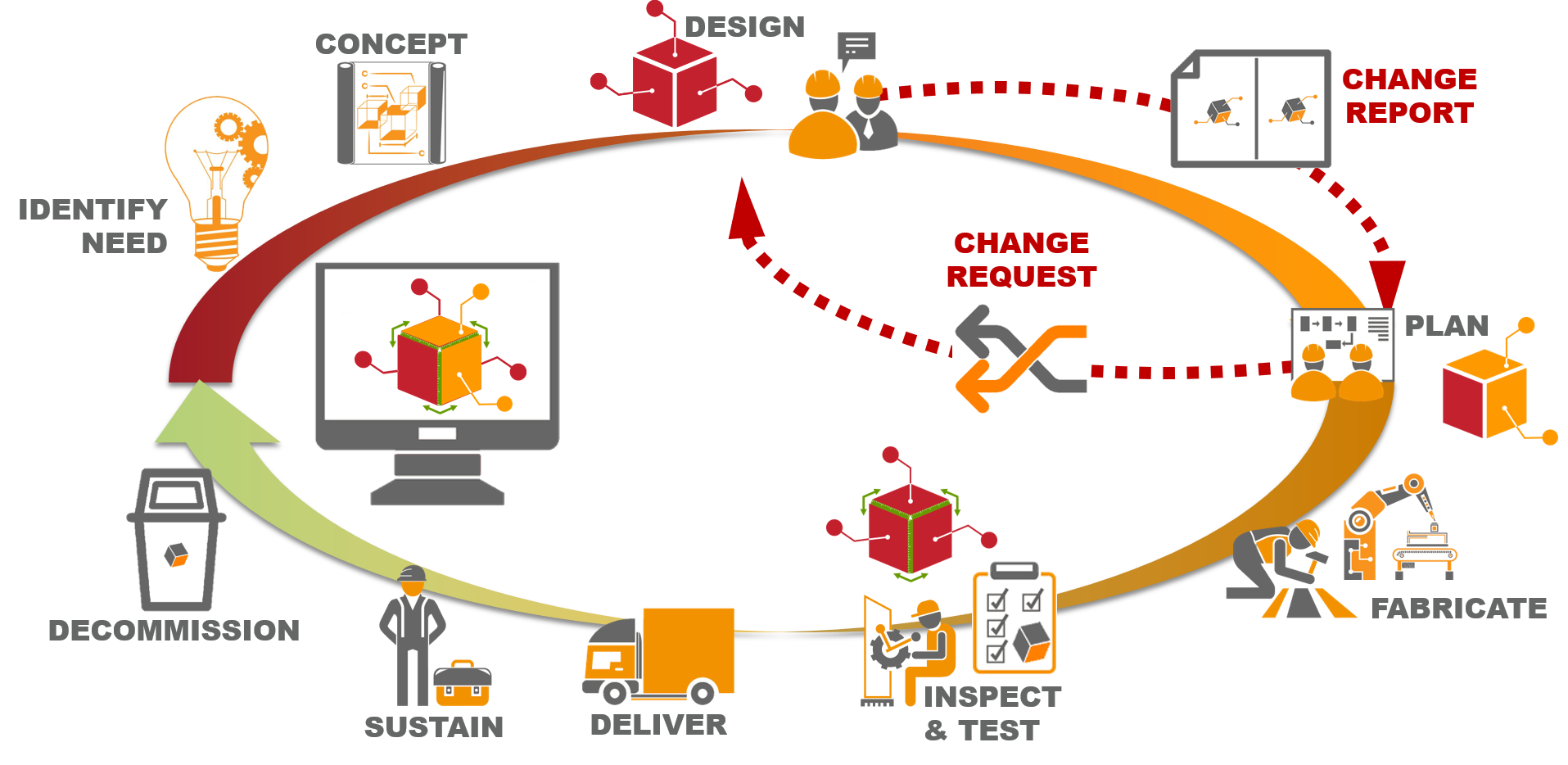

| An integrated digital approach that uses authoritative sources of systems data and models as a continuum across disciplines to support lifecycle activities from concept through disposal. |

| The ability to develop, validate, use, curate, and maintain technically accurate digital systems and models of systems, subsystems, and their components, at the appropriate level of fidelity to ensure test activities adequately simulate the environment in which a system will be deployed. |

| The interconnected infrastructure, environment, and methodology (process, methods, and tools) used to store, access, analyze, and visualize evolving systems data and models to address the needs of the stakeholders. |

| A digital enterprise is a company where all business processes are driven by digital technology and big data. |

| Digital manufacturing is the use of an integrated, computer-based system comprised of simulation, 3D visualization, analytics and collaboration tools to create product and manufacturing process definitions simultaneously. |

| The process of performing metrology operations on an end item using digital data which is connected, traceable, and automated. |

| A model that is digitally represented. |

| Requirements of any digital data files that disclose, directly or by reference, the physical or functional requirements, including data files that disclose the design or acceptance criteria of a product. Examples of DPD include the following: The digital definition and fully dimensioned two-dimensional (2D) drawing sheets. Three-dimensional (3D) data model and simplified or reduced content 2D drawing sheets. The 3D model with design characteristics displayed as text. Any other data files that define a product in its entirety. |

| result of a cryptographic transformation of data that, when properly implemented, provides a mechanism for verifying origin authentication, data integrity and signatory non-repudiation |

| The communication framework that allows a connected data flow and integrated view of an asset’s data (i.e., its Digital Twin) throughout its lifecycle across traditionally siloed functional perspectives. |

| Digital transformation is the process of digitalizing business processes and information in the pursuit of a more agile and efficient business model. |

| A digital twin is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. |

| The process of moving from analog processes to digital processes, connecting data elements representing a product, managing configurations and their dependencies to transform business; moving to a digital business. |

| Digitalization in education refers to the use of digital technology to teach students. |

| A numerical value(s) or mathematical expression in appropriate units of measure used to define the shape, size, orientation, or location of a part feature or between part features. |

| Engineering effort directly related to specific end products. |

| A modeling method that allows designers to interact directly with the geometry of the model. |

| A dimension with an associated plus/minus tolerance or limit dimension values. NOTE: Where a plus/minus general tolerance is applied to a dimension, the dimension is considered a directly toleranced dimension. |

| Central elements in a collaborative environment that authoritatively maintain the system design and behavioral information for alternative designs as needed for Modeling and Simulation (M&S) analyses by all authorized users. In particular, the DPD should possess strong inter-networking capabilities to maintain coordinated system design (structural) and performance views of the system under development. It should incrementally reflect changed performance parameters in response to design changes and address the resulting performance impacts on system operations. |

| An engineering document or digital data file(s) that discloses (directly or by reference), by means of graphic or textual presentations, or by combinations of both, the physical or functional requirements of an item. |  |

| The arrangement and organization of information within a drawing. This includes such features as the size and arrangement of blocks, notes, lists, and revision information and use of optional or supplemental blocks. |

| The two-dimensional geometric elements and annotations that define an item and the product definition elements of the sheet format in accordance with ASME Y14.1 or ASME Y14.1M. |  |

| Requirements of the drawing and associated parts lists, specification, or purchasing document to which the product is to be produced from, including any notes, specifications, and lower-level drawings invoked. |

| A block diagram or indentured list that identifies all drawings applicable to an end item or program and illustrates the next higher and subordinate relationships that exist between those drawings. |

| A characteristic, which is presented on a graphical drawing. |

| A Product Characteristic, which is supplemented by a Product Requirement Association augmentation. |

| Dimensions in a drawing file derived from the 3D model. Driven dimensions reflect changes to part or assembly geometry, but you cannot modify their values in the drawing. The association is one-way; from the model to the drawing. |

| A dimension that when modified in the drawing is also modified in the 3D model from which it originated. |

| A replica of an engineering drawing created to serve as the official record of the item when the original has been lost. |

| A computerized document intended for presentation to humans. |

| A defined method to sign an object in electronic environments. It provides means to authenticate the signatory and the signed object in an unambiguous and safe way by attaching to or logically associating data in electronic form to other electronic objects. (See NAS9300-005) |

| The condition of a derivative being embellished from its source with respect to an intended use. |

| The final production product when assembled, or completed, and ready for issue or deployment. |

| An item, such as an individual part or assembly, in its final or completed state. |  |

| The engineering bill of materials reflects the design of the product rather than the manufacturing process of the product. eBOMs are typically driven from the CAD model and are usually centric to the final assemblies list of parts or components. |

| The documentation by which a proposed engineering change is submitted to the responsible authority recommending that a change to an original item of equipment be considered, and the design or engineering change be incorporated into the article to modify, add to, delete, or supersede original parts. |

| Engineering documents such as drawings, associated lists, accompanying documents, specifications, standards, or other information prepared or used by a design activity and relating to the design, manufacture, procurement, testing, or inspection of items. |

| Engineering drawings, 3Di viewables, native CAD models, neutral CAD models or a combination of these, which define an item by means of graphic and textual presentations, the physical and/or functional requirements of an item, sufficient to fulfill its TDP element and level requirements. Engineering design data comes in three levels corresponding to its TDP level requirements. |

| A digital signature with which the data producer asserts that the prepared data fits with the process and quality requirements from the engineering point of view. (NAS9300-005) |

| Activities that enable an organization to act as a MBE, but do not directly add value to a product. |

| A unique identifier used to distinguish one activity or organization from another activity or organization. Examples of enterprise identifiers are: Commercial and Government Entity (CAGE) Code; Department of Defense Activity Address Code (DODAAC); Dun & Bradstreets Data Universal Numbering System (D-U-N-S); North Atlantic Treaty Organization (NATO) CAGE (NCAGE) Code; ISO/SAE WMI Code and GS1 Company Prefix. An enterprise identifier code is uniquely assigned to an activity by an issuing agency registered in accordance with procedures outlined in ISO/IEC 15459-2. An enterprise may be an entity such as a design activity, manufacturer, supplier, depot, program management office, or a third party. |

| A system that manages as-routed data and is the authoritative source for schedule, producer information, and cost. |

| Integrates and manages simulation and analysis data and processes across the product development processes. ESM’s primary components include knowledge capture and replication and integrated simulation management. Also called Simulation Data Management or Simulation Lifecycle Management. |

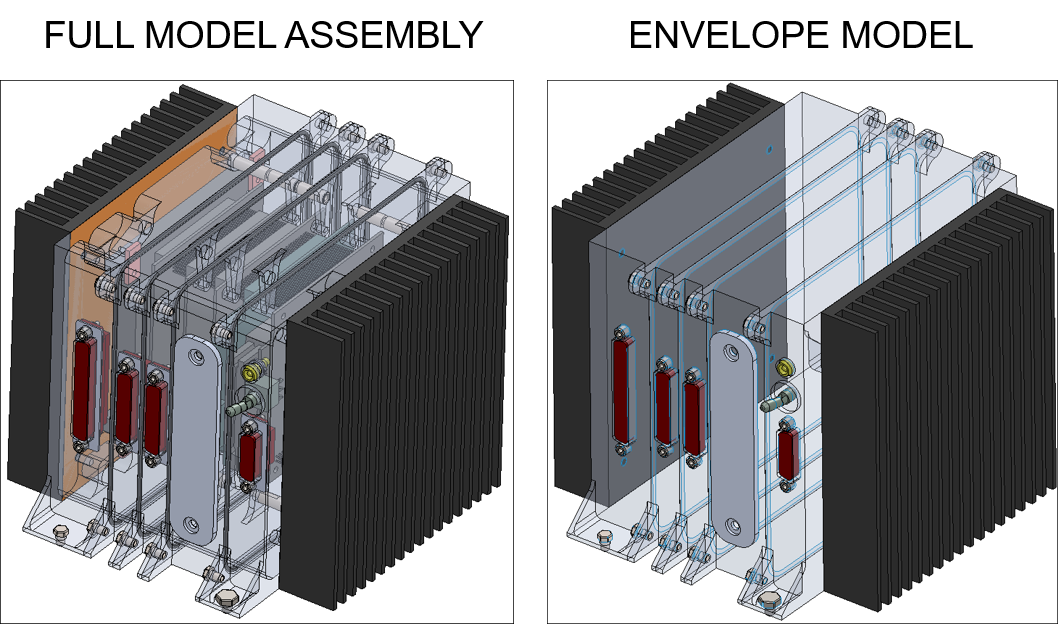

| A part created to represent a predetermined set of components in an assembly. The envelope uses simple geometry to reduce system memory usage and looks similar to the components it represents. |

| Product definition data that discloses the basic technical data and performance requirements necessary for development, or design selection of an item where it is desirable to have all features other than those shown on the drawing left to the ingenuity of the supplier. An envelope drawing does not establish item identification. |

| A solid model representation of the outer shape of an assembly that is represented as a single part. |  |

| A tolerance in which variation is permitted equally in both directions from the specified dimension or true profile. |

| The condition of a derivative being functionally equivalent to its source with respect to an intended use. |

| computer-interpretable format used for storing, accessing, transferring, and archiving data |

|

explicit identification of the definition given within another source

Note 1 to entry: That source provides all the information necessary to unambiguously recreate the element; the information can be referenced rather than recreated.

|

| A collection of parts (or assemblies or features) that are essentially similar, but deviate slightly in one or two aspects, such as size or detail features. For example, wood screws come in various sizes, but they all look alike and perform the same function. Thus, it is useful to think of them as a family of parts. Parts in Family Tables are also known as table-driven parts. |

| All products of the same classification, design, construction, material, type, etc., produced with the same production facilities, processes, and quality of material, under the same management and quality controls, but having the acceptable variety of physical and functional characteristics defined and specified in the applicable engineering documentation. |

| A physical portion of a part (such as a surface, pin outside diameter, hole, or slot) or its representation on drawings, models, or digital data files. |

| A rectangle divided into compartments containing the geometric characteristic symbol followed by the tolerance value or description, modifiers, and any applicable datum feature references. |

| A tag used to identify a geometric feature, face, or element. |

| A general term that is used in ASME Y14.5 Standard to refer to instances in which both a regular and an irregular feature of size apply. |

| The tolerance zone framework that controls the basic relationship between the features in a pattern with that framework constrained in rotational degrees of freedom relative to any referenced datum features. |

| The joining of the major sections to perform a complete unit. |

| The final process model for a process definition. |

| A numerical technique for finding approximate solutions to systems of partial differential equations. FEM is applied to calculations of stress, strain, and deflection, temperature distribution and heat transfer, electromagnetic and similar problems. FEM, also called finite element analysis (FEA), is characterized by the subdivision of solid objects into tetrahedral or hexahedral finite elements. Thin-walled objects may be approximated by two-dimensional shell elements having three or four sides. |

| A planned, complete, independent, and documented inspection and verification process to ensure that prescribed production processes have produced an item conforming to engineering drawings, DPD, planning, purchase order, engineering specifications, and/or other applicable design documents. |

| The forms and package of documentation for a part number, subassembly, or assembly, including associated FAI results. |

| The initial group of one or more parts that are the result of a planned process designed to be used for future production of these same parts. |

| The condition of a surface or derived median plane having all elements in one plane. |

| The condition in which no externally introduced forces other than gravity are applied to a part. |

| A type of bounded volume region that encloses the entire part and in which other parts cannot be located or intersected. |

| A model that includes every basic dimension and tolerance value necessary to produce the part by visual inspection of the annotated model alone. Also known as a 3D Drawing. |

| The formal examination of functional characteristics of a configuration item, or system, to verify that the item has achieved the requirements specified in its functional and/or allocated configuration documentation. |

| A characteristic tag used for a non-product characteristic or general usage. |

| An iterative software-based process that uses human entered constraints and incorporates analysis, machine-learning, and simulations to interpret design requirements for production of multiple 3D geometric models for user evaluation. |

|

related to shape information

EXAMPLE points, curves, surfaces, and volumes |

|

a concept characterizing the size, form, orientation or location of a feature or of a component of a feature

EXAMPLE diameter, flatness, parallelism, or position. |

| A general term for a system of applying dimensional annotations and tolerances to drawings or models defined by ANSI Standard Y14.5. |

| A graphic entity used in a data set. For example: point, line, plane, surface, solid, coordinate system, or crosshatching. |

| The set of data and resources used to represent the precise size, position, and shape of an object, often a production. |

| Geometric Tolerance | GT, GeoTol |

|

| A tolerance indicated using a geometric characteristic symbol. |

| Geometry consists of the mathematical description of individual part surfaces. Modern CAD systems employ what is called the boundary representation method for describing model geometry. Boundary representations consist of curves, surfaces, edges, and faces. In a valid model, the faces meet at the edges to form a closed volume. |

| The level of detail of the geometry as represented in a model. |

| Specifies, with tolerance, how physical characteristics are varied spatially (e.g., changes in material composition, color, density, porosity, or unit cell size). |

| Pictorial representation of a 3D model or 2D drawing. Generally it is captured as a screen shot. The image can be isometric or planar, cartoon-like, 3D, realistic or line art. |

| A hierarchical diagram of 3D model features that shows their relationships and the order in which they were created. |

| The intermediate process model(s) with a process definition. |

| Industrial Internet of Things (IIoT), also known as Industry 4.0, is the application of an IoT framework to devices and machines within manufacturing. The IIoT is part of a larger concept known as the Internet of Things (IoT). The IoT is a network of intelligent computers, devices, and objects that collect and share huge amounts of data. The collected data is sent to a central Cloud-based service where it is aggregated with other data and then shared with end users in a helpful way. |

| The fourth industrial revolution, occurring now, is manufacturing operations digitally transformed to leverage connected data, machines, and people. A connected factory may use Additive Manufacturing (AM), cybersecurity, Artificial Intelligence (AI), Augmented Reality (AR), autonomous robots, big data analytics, cloud computing, the Internet of Things (IoT), Machine Learning (ML), simulation, and technologies not yet invented to reduce waste in their processes. |

| Facts, concepts, or instructions |

|

Formal model of information

Note 1 to entry: In ISO 10303, an information model is based on the Object-relationship modeling technique that organizes the product data as represented in different system aspects.

Note 2 to entry: In ISO 10303, information models are developed using EXPRESS modeling language.

EXAMPLE ISO 10303-242.

|

| A derivative model with one-way associative propagation of source model changes. |

| A worst-case boundary generated by the collective effects of the smallest feature of size (MMC for an internal feature of size, LMC for an external feature of size) and the applicable geometric tolerance. |

| One item, or two or more items joined together, that is not normally subject to disassembly without destruction or impairment of designed use (e.g., transistor, composition resistor, screw, transformer, and gear). |

| 3D CAD with two or more bodies and/or two or more Mono-Detail Models that represent an inseparable assembly (e.g., weldment). |

| a measurement of characteristics on a physical part to determine whether the features are within allowed tolerance, commonly in order to accept or reject the part |

| A tolerance or specification applied to a part feature or product that requires verification. |

| Information about the circumstances of a quality measurement process |

| A collection of part and assembly models, combined in an assembly for the sole purpose of describing how a component or subassembly mounts in a very large structure. This assembly does not have a next higher assembly, nor is it typically the top assembly. |

| A model in which the product described is an installation, showing parts or assemblies and a partial or complete representation of the installation site. |

| Each instantiation of a component is called an instance. It may appear that the part model (component) is copied several times within a single assembly, yet the other representations are merely visualizations of the source data. |  |

| A parts list prepared and revised as part of an engineering drawing. |

| An associative link to a part external to the one being worked on. These references are sometimes called external references. For example, a hole may reference its centerline location from another part, creating an associated link from the hole feature to the other part. |

| A mode of operation performed by a person interacting with automation. |

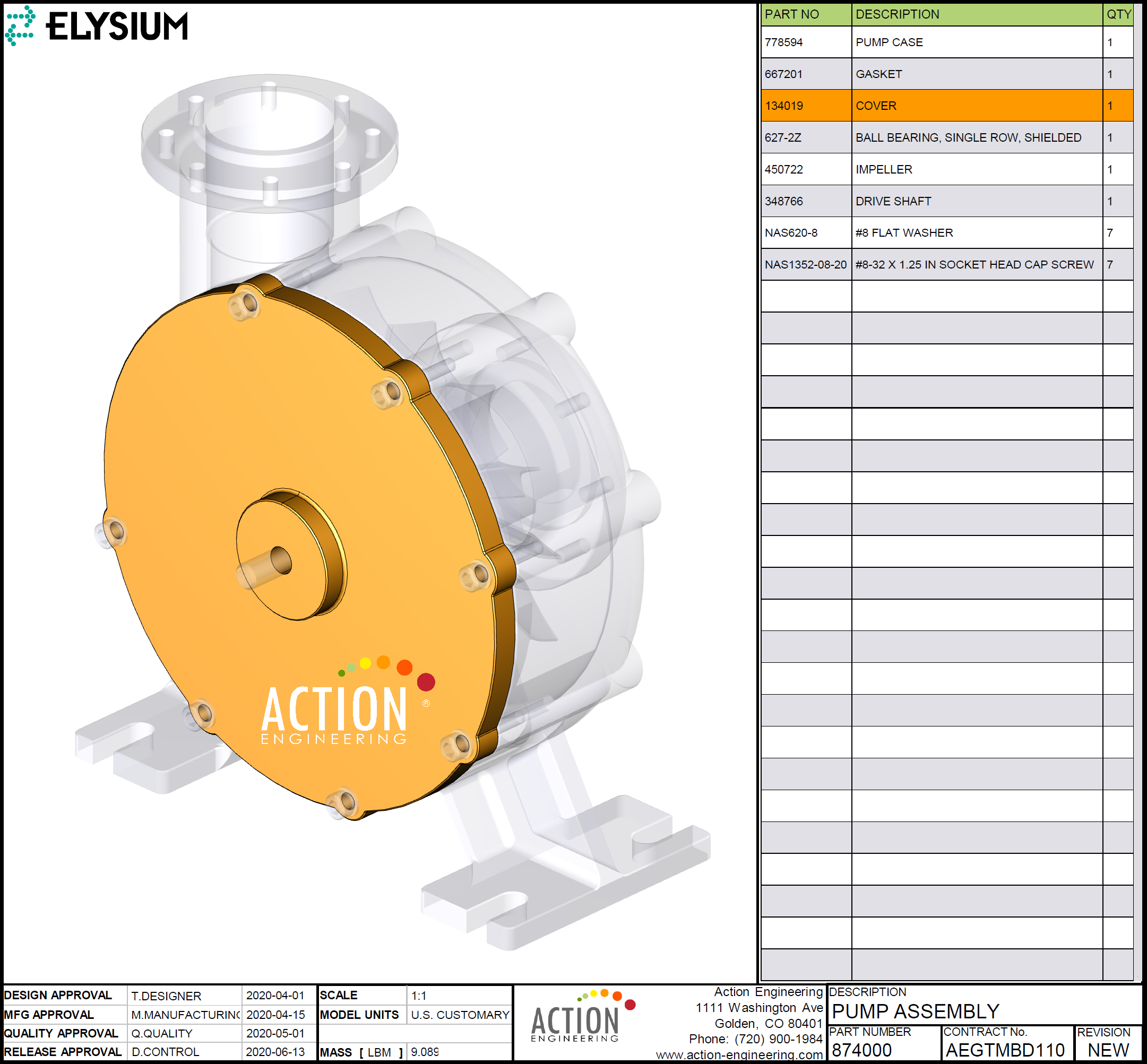

| An automatically generated parts list from the CAD BOM that is optimized for the human user experience and persists digital associativity between the component and the parts list. The purpose is for the human reader to read, view, and navigate the parts list information within the context of the geometry and components. |

| A condition that exists when two or more items possess such functional and physical characteristics as to be equivalent in performance and durability, are capable of being exchanged one for the other without alteration on the items themselves or of adjoining items, except for adjustment, and without selection for fit and performance. |

| An item that possesses functional and physical characteristics equivalent in performance to another item of similar or identical purposes, and is capable of being exchanged for the other item without selection for fit or performance, and without alteration of the items themselves or of adjoining items, except for adjustment. |

| The functional and physical characteristics required to exist at a common boundary or connection between persons, between systems, or between persons and systems. A system external to the system being analyzed that provides a common boundary or service that is necessary for the other system to perform its mission in an undergraded mode, e.g., a system that supplies power, cooling, heating, air services, or input signals. |

| A gap or gaps in a feature that divide it into two or more features (e.g., a slot or a groove). |

| There are two types of irregular features of size, as follows: (a) a directly toleranced feature or collection of features that may contain or be contained by an unrelated AME that is a sphere, cylinder, or pair of parallel planes. (b) a directly toleranced feature or collection of features that may contain or be contained by an unrelated AME other than a sphere, cylinder, or pair of parallel planes. |

| A nonspecific term used to denote any unit or product, including materials, parts, assemblies, equipment, accessories, and computer software. |

| The Part or Identifying Number (PIN) for a specific item along with the original Design Activity Identification (DAI). |

| a characteristic of a feature, material, process, or part whose variation has a significant influence on product fit/function, safety/compliance, performance, service life, or manufacturability |

| An assembly which has a total of all components (Company, Industry (including fasteners), Supplier), including all the instances (not unique parts) in the assembly are between 200 and 1000 parts. |

| Three dimensional geometric arrangement composed of connective links between vertices (points) creating a functional structure. |

| The worst-case boundary that exists on or inside the material of a feature(s) and is defined by the combined effects of size and geometric tolerances. |

| The condition in which a feature of size contains the least amount of material within the stated limits of size, e.g., maximum hole diameter or minimum shaft diameter. |

| Lifecycle Data consist of information that describes the state of the part within a controlled procedure for development, review, release for manufacture, retention for maintenance and upgrades, and retirement and disposal. For example, the revision level and release date are lifecycle data that describe the administrative state of the part and change as the product moves through its review and approval cycle. Lifecycle data dont describe properties inherent in the part (such as the material type or manufacturer) that are necessary information to make or procure the part. |  |

| A management process applied throughout the life of a system that bases all programmatic decisions on the anticipated mission-related and economic benefits derived over the life of the system. It includes the implementation, management, and oversight by the designated Program Manager (PM) of all activities associated with the acquisition, development, production, fielding, sustainment, and disposal of a DoD system across its life cycle. |

| A 3D CAD data set sufficiently defined to provide a visual understanding of the item, but which does not contain full design disclosure. Generally external interface characteristics and features such as weight and center of gravity will be sufficiently defined for the intended purpose. Sometimes referred to as an envelope model, shrink-wrap model or cosmetic model. |

| Storage of a copy of data in an appropriate way for record, certification and legal purposes. The data will be preserved and kept available for a use within the archive and possibly for further re-use. With certified conversion processes, the native data representation generated by the source system can be converted into a representation which is appropriate for long term archiving. To fulfill legal and certification requirements, the stored form can be an accurate or approximate representation of the source. Integrity must be ensured by a digital signature. The data is retained over the long term. Invariance is mandatory. Business, legal and certification requirements are covered. (NAS9300-003, 3.2.5) |

| A capability that preserves information and makes it available for communities of interest. |

| A product definition dataset that includes a model-based definition. |

| A tool that an organization uses to assess itself as, and facilitate transition to, a model-based enterprise. |

| An operation in the construction of a section that joins a number of subassemblies. |

| The data required for the release, control, and storage of product definition data as well as other relevant engineering data. |

| A mode of operation performed by a person without automation. |

| The process of making an item using machinery, often on a large scale, and with division of labor. |

| The single source authority for manufacturing. It is a connected derivation of the Design Authority model. Model data is derived from the design authority, but manipulated, translated, verified, and synced as required by the change management process back to the design authority. |

| The manufacturing bill of materials reflects the manufacturing process of the product rather than the design of the product. mBOMs are typically driven by the eBOM and also include all items related to the end product, including packaging or shipping. |

| A system that manages as-built manufacturing information and is the authoritative source for execution records, assembly records, non-conformance records, and dimensional inspection records. It most often captures real-time data. |

| May contain some or all of the Product Model data elements but will vary based on the manufacturing needs of the product. For example, it may be a single 3D solid model in neutral format containing only geometry. The elements contained in the Manufacturing Model are translated and verified from and against the Design Authority model. |

| Software provides full visibility into manufacturing processes to optimize manufacturing operations performance. |

| A set of data defining the process flow and test requirements for new product to be manufactured, which identifies the people, equipment, and facilities required. |

| A structured evaluation of a technology, component, manufacturing process, weapon system or subsystem using Manufacturing Readiness Levels (MRLs). It is performed to define the current level of manufacturing maturity, identify maturity shortfalls and associated costs and risks and to provide the basis for manufacturing maturation and risk management. |

| A measure used to assess the maturity of a given technology, component or system from a manufacturing prospective. The purpose of MRLs is to provide decision makers at all levels with a common understanding of the relative maturity and attendant risks associated with the manufacturing technologies, products, and processes under consideration. There are ten MRLs, with MRL 1 being the least mature and MRL 10 being the most mature. |

| A system that manages as-planned data and is the authoritative source for the mBOM, inventory, and equipment. |

| information about the circumstances of a manufacturing process. |

| A controlled set of instructions that describe in detail how particular tasks, procedures, or processes must be performed; provide a referenced, repeatable framework for communicating the steps needed to complete a task. |

| A set of technical data which is the controlling source for any subsequent technical data output. All changes to the technical data must originate on the master technical dataset. There can be only one instance of the master technical data which is typically in the native CAD format and maintained by the current design activity. |

| A document that shows the dimensional limits or grid locations applicable to any or all parts of a rigid or flexible printed board, including the arrangements of conductive and nonconductive patterns or elements, size, type, and location of holes; and any other information necessary to describe the product to be fabricated (see IPC T-150). |

| A set of technical data which is the controlling source for any subsequent technical data output. All changes to the technical data must originate on the master technical dataset. There can be only one instance of the master technical data which is typically in the native CAD format and maintained by the current design activity. |

| A methodology and system used to plan and manage manufacturing operations. The BOM for products released to manufacturing and the product routing definition are key parts of the MRP system’s database. |

| In the MBE Maturity Index, a state of maturity that contains a set of assertions. |

| The condition of the design maturity for the specified use of the data set within the product life cycle. |

| The worst-case boundary that exists on or outside the material of a feature(s) and is defined by the combined effects of size and geometric tolerances. |

| The condition in which a feature of size contains the maximum amount of material within the stated limits of size, e.g., minimum hole diameter or maximum shaft diameter. |

| an estimate of a dimension associated with a feature or features on a physical part generated using a physical device |

|

a measurement resource that provides an indication for a dimensional characteristic of a workpiece

Note 1 to entry: This indication may either be a value (variables) or simply conformance (attributes).

|

| a complete plan that contains information on what and how to measure |

| a piece of dimensional metrology equipment that can be used to measure features and/or characteristics on a workpiece |

|

the measured value of an actual feature or characteristic

Note 1 to entry: A measurement result is obtained by measuring a feature or characteristic with a measurement resource. |

| An assembly which has a total of all components (Company, Industry (including fasteners), Supplier), including all the instances (not unique parts) in the assembly are between 200 and 1000 parts. |

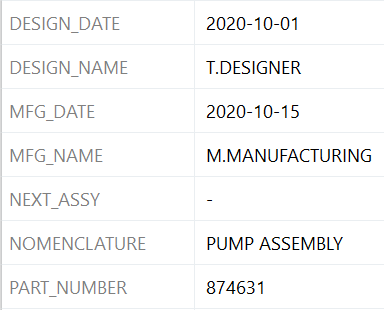

| Data about data. For example, the file name is meta data about a CAD design held as a file. |

| Organizational elements that capture data providing information about a product definition data set. |

| The portion of the data set that contains model geometry and supplemental geometry. |  |

| Geometric elements in product definition data that represent an item. |

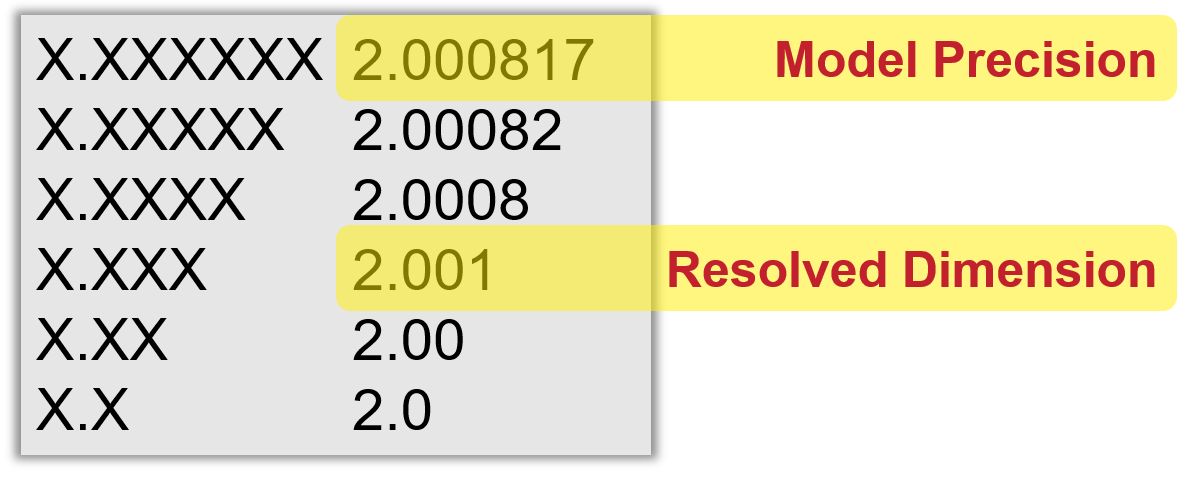

| The highest number of significant digits set in the CAD model document. |

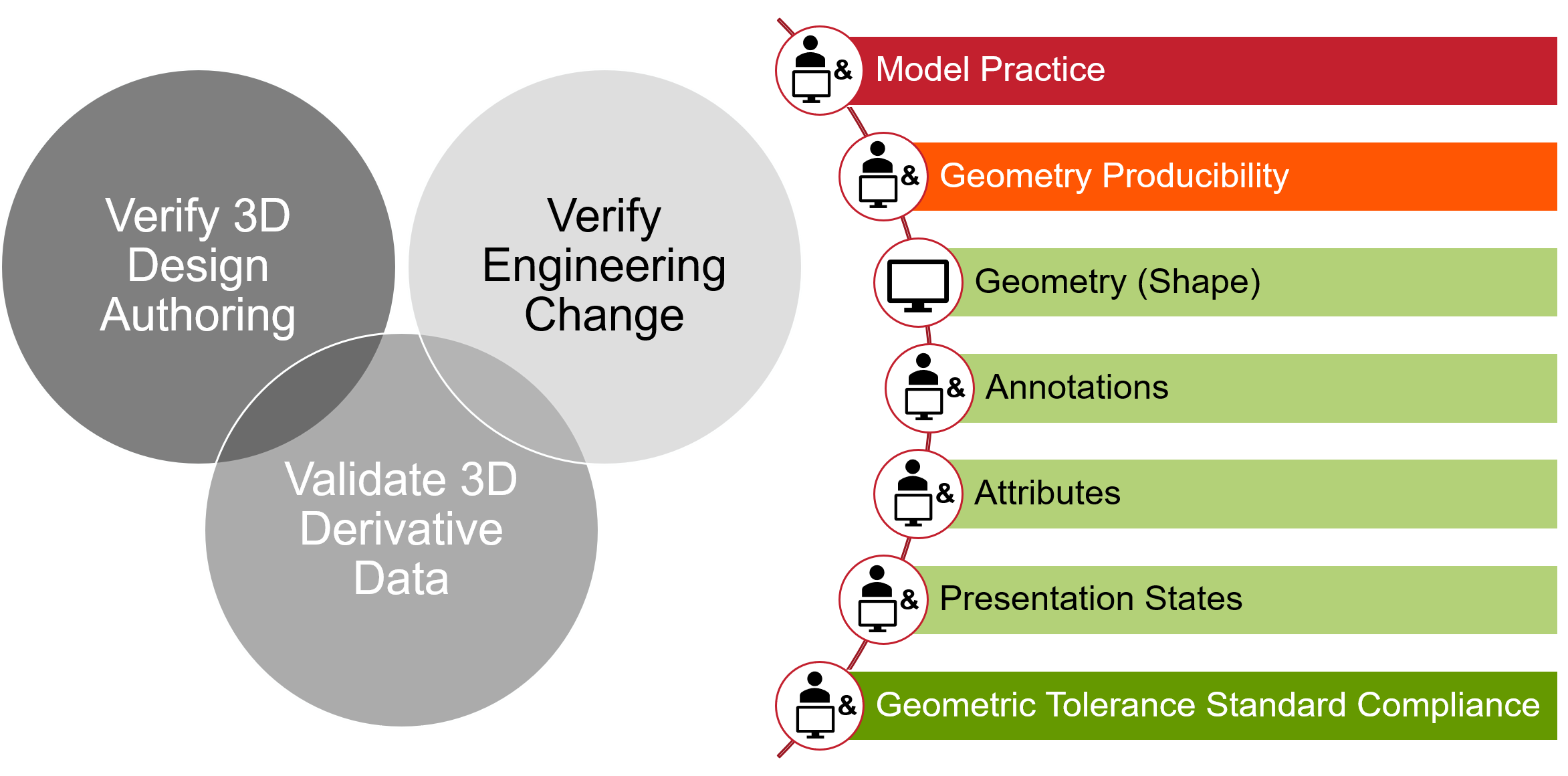

| An organization, grouping, naming convention and direction for completeness of models, annotations, attributes and metadata, included in the original model. These basic building blocks facilitate accurate archival and data exchange of TDP Type: 3D. |

| A Model Tree is a list of every feature in a part file including the datums and coordinate system. Creo Parametric displays the model structure in a hierarchical tree format with the current part or assembly as root object at the top of the tree. The subordinate parts or features are displayed below the root object. |

| The numerical value derived by interrogating the model that quantifies the form and spatial relationships of the geometry composing a design model, or assembly of models, to the precision (number of decimal places) of the computer system. |

| A characteristic, which is represented within a model-based definition model. |

| An annotated model and its associated data that define the product in a manner that can be used effectively without a drawing graphic sheet. |

| A process that uses models throughout the product lifecycle. |

| An organization that uses digital methodologies as the foundation to enable deployment of products from concept to disposal. |

| An ecosystem defined by software, hardware, infrastructure, and people that supports both a Model-Based Engineering approach, and a Model Based Enterprise. |

|

An environment [in that] the Design Data can be consumed by the value streamto plan, produce, fabricate, assemble, inspect and certify, [and] maintain and sustain parts and assemblies to meet requirements.

T. D. Hedberg Jr., M. E. Sharp, T. M. M. Maw, M. M. Helu, M. M. Rahman, S. Jadhav, J. J. Whicker & A. Barnard Feeney (2021): Defining requirements for integrating information between design, manufacturing, and inspection, International Journal of Production Research, DOI: 10.1080/00207543.2021.1920057. |

|

The conformance of the physical product and process to the requirements of digital product definitions and process specifications using measurement planning, execution, and evaluation in combination with 3D annotated models and associated data.

T. D. Hedberg Jr., M. E. Sharp, T. M. M. Maw, M. M. Helu, M. M. Rahman, S. Jadhav, J. J. Whicker & A. Barnard Feeney (2021): Defining requirements for integrating information between design, manufacturing, and inspection, International Journal of Production Research, DOI: 10.1080/00207543.2021.1920057. |

| Systems Engineering is a transdisciplinary and integrative approach to enable the successful realization, use, and retirement of engineered systems, using systems principles and concepts, and scientific, technological, and management methods. |

| An acquisition and design strategy consisting of a technical architecture that uses system interfaces compliant with widely supported and consensus-based standards (if available and suitable). The strategy supports a modular, loosely coupled and highly cohesive system structure that allows severable system components at the appropriate level to be incrementally added, removed, or replaced throughout the life cycle of a system platform to afford opportunities for enhanced competition and innovation. |

| 3D CAD that represents a single piece part. |

| Identical characteristics that occur at more than one location (e.g., 4 places), but are established by a single set of drawing or DPD requirements (e.g., rivet hole size, dovetail slots, corner radii, chemical milling pocket thickness). |

| A 3D model in the (usually proprietary) format of the CAD system in which it was originally derived or modeled. |

| CAD data as created in its original authoring software format. In general, only the original authoring software format is capable of reading, editing and interpreting native CAD data. (Examples: CREO, CATIA, Autodesk, SolidWorks, etc.) Generally native CAD data is the only format suitable to serve as master technical data. Native CAD data may also serve as authoritative technical data. |

| The format in which a software application stores its data, where that format is part of the design of the software. |

| A model in the format of its originating software application (e.g., Creo). |

| Situation when parts are made in one build cycle and are located such that their bounding boxes, arbitrarily oriented or otherwise, will overlap. |

| independent of a specific computer system |

| CAD data which is derived from the native format and converted into a format which can be imported into other CAD software. Neutral CAD data is created to a widely available national or international standard (e.g. STEP). In general, neutral CAD data cannot serve as master technical data but may serve as either reference technical data or authoritative technical data. |

| The theoretically perfect representation of a design's geometry as defined by the features' nominal sizes and basic dimensions. |

| The designation used for purposes of general identification. (USAS B4.1) |

| A standardization document developed by a private sector association, organization or technical society which plans, develops, establishes or coordinates standards, specifications, handbooks or related documents. Company standards are not considered as non-Government standardization documents. |

| An engineering drawing that provides requirements, such as procedures or instructions, applicable to an item when it is not convenient to include this information on the applicable part drawing (e.g., a test requirements drawing or logic diagram). |

| An MMB and an LMB, where at least one boundary is a specified shape that is not a uniform offset from true profile. |

| Textual information that further delineates the requirements of the item represented. |

| Widely accepted and supported standards set by recognized standards organizations or the marketplace. These standards support interoperability, portability, and scalability and are equally available to the public at no cost or with a moderate license fee. |

| A system whose technical architecture adopts open standards and supports a modular, loosely coupled, and highly cohesive system structure. This modular open architecture includes publishing of key interfaces within the system and relevant design disclosure. |

| A characteristic, which is created to identify an operation or process requirement for the product realization process of a product or of a feature of a product. |

| The mechanisms that integrates change and the ability to adapt change within an organization. |

| A nongeometric model element selected for organization or grouping by a standardized method. |

| A non-geometric model element selected for organization by a standardized method. |

| The current design activitys drawing on which the official revision record is kept. |

| The design activity originally responsible for the design and identification of an item whose drawing number and design activity identification is shown in the title block of the drawings and associated documents. |

| Originating 3D Model, generally in native CAD software format, that is the working model for changes to geometry, annotations and attributes. From the original model flows the product model which is controlled as the record of authority. All data elements within the model maintain associativity to one another. |

| The model used to keep the design intent for Long Term Archiving in the context of certification & legal requirements for proof. |

| An orthographic view is the figure outlined upon the projection plane by means of the system of orthographic projection. Orthographic views may be constructed, or they may be saved views that are automatically gen-erated from models or design models. Orthographic view requirements apply equally to constructed and automatically generated views unless exception is stated. |

| A worst-case boundary generated by the collective effects of the largest feature of size (LMC for an internal feature of size, MMC for an external feature of size) and the applicable geometric tolerance. |

| PDM System | Product Data Management System |

|

| An information system that implements product data management. |

| The condition of a line element, surface, tangent plane, center plane of feature, or feature axis at an implied or specified basic 0° (parallel) angle relative to one or more datum planes or datum axes. |

| A term used to classify curves for which the path is described by a mathematical function rather than a set of coordinates. A parameter within the function (often specified as u or v) is varied from 0 to 1 to define all the coordinate points along the curve. |

| An assembly in which a component position updates as the referenced components move or change. |

| A modeling process with the ability to change the shape of model geometry as soon as the dimension value is modified. |

| A model into which child models “tree” up. Also referred to as the next higher assembly/installation. |

| One item, or two or more items joined together, that is not normally subject to disassembly without destruction or impairment of designed use (e.g., transistor, composition resistor, screw, transformer, and gear). |  |

| A 3D model representation of a single hardware item. |

| The identifier assigned by the original design activity or by the controlling nationally recognized standard that uniquely identifies, relative to that design activity, a specific item. |

| An organizing principle that enables product data management to relate all product lifecycle data to a single point of reference. |

| Parts List | PL |

|

| A tabulation of all parts and bulk materials used in the item(s), except those materials that support a process and are not retained, such as cleaning solvents and masking materials. NOTE: Other terms used to describe a parts list are list of materials, bill of materials, stock list, and item list. |  |

| Two or more features to which a position or profile geometric tolerance is applied and that are grouped by one of the following methods: nX, n COAXIAL HOLES, ALL AROUND, ALL OVER, between A and B (A ? B), from A to B (A ? B), n SURFACES, simultaneous requirements, or INDICATED, where n in these examples represents a number. |

| The tolerance zone framework that controls the basic relationship between the features in a pattern with that framework constrained in translational and rotational degrees of freedom relative to the referenced datum features. |

| The record of heritage that proves the veracity of a data item. |

| A specification that states requirements in terms of the required results with criteria for verifying compliance, but without stating the methods for achieving the required results. A performance specification defines the functional requirements for the item, the environment in which the item operates and interfaces, and the interchangeability characteristics. |

| A work statement for performance-based acquisitions that describes the required product or service in clear, specific and objective terms with associated measurable outcomes. |

| The condition of a line element, surface, tangent plane, center plane of feature, or feature axis at an implied or specified basic 90° (perpendicular) angle relative to one or more datum planes or datum axes. |

| Physical asset configuration is a comprehensive, actionable digital twin, or virtual representation, that contains up-to-date information on the composition and structure of a managed item or property. |

| Physical examination of the actual configuration of the item being produced. It verifies that the related design documentation matches the item as specified in the contract. The system product baseline is finalized and validated at the PCA. |

| A single piece not normally subject to disassembly without destruction or impairment of use, such as resistors, transistors, relays, and gears. |

| The location of one or more features of size relative to one another or to one or more datums. |

| The manner in which information is displayed for use by a human. |

| A retrievable collection or set of model display elements arranged for formal display to the viewer. |

|

[Primary] Any information that defines the physical or functional characteristics of a product, to ensure the design intent.

[Alt] The activity that defines a process that realizes a product. |

| A dataset that contains process definition. |

| A system model that encapsulates a process definition. |

| A specification document (not a drawing) that defines the technical requirements (design-to, performance, environmental, testing, reliability, maintainability, etc.) for an item to be developed by a supplier. |

| Product Definition Data, Technical Data, Item, Feature, Drawing, Item. IdentificationIncludes materials, parts, components, subassemblies, assemblies, and equipment. The term product shall also encompass a family of products. |

| A tolerance or specification applied to a feature or product that requires verification. A characteristic has a local designation identifier(s) and may have a criticality associated with it. |

| An identifier, which is used as the basis for both a Product Characteristic Reference Identifier (i.e., Tag or UUID), and a Product Characteristic Instance Identifier. |

| An optional identifier that is concatenated with a Product Characteristic Base Identifier, which uniquely identifies a Product Characteristic Instance Identifier. |

| An identifier (i.e., Tag or UUID), of an instance of a Product Characteristic Reference Identifier, which combines a Product Characteristic Base Identifier with an optional Product Characteristic Extension Identifier. |

| A product characteristic tag used as an instance identifier. |

| An identifier (i.e., Tag or UUID), which references a verification requirement annotation as a Product Characteristic, which contains the Product Characteristic Base identifier. |

| A product characteristic tag used as a reference identifier. |

| A characteristic tag used for a product characteristic. |

| A representation of information about a product in a formal manner suitable for communication, interpretation, or processing by human beings or by computers. |

| A system that manages as-designed data and is the authoritative source for the geometry, attributes, CAD BOM, and revision. |  |

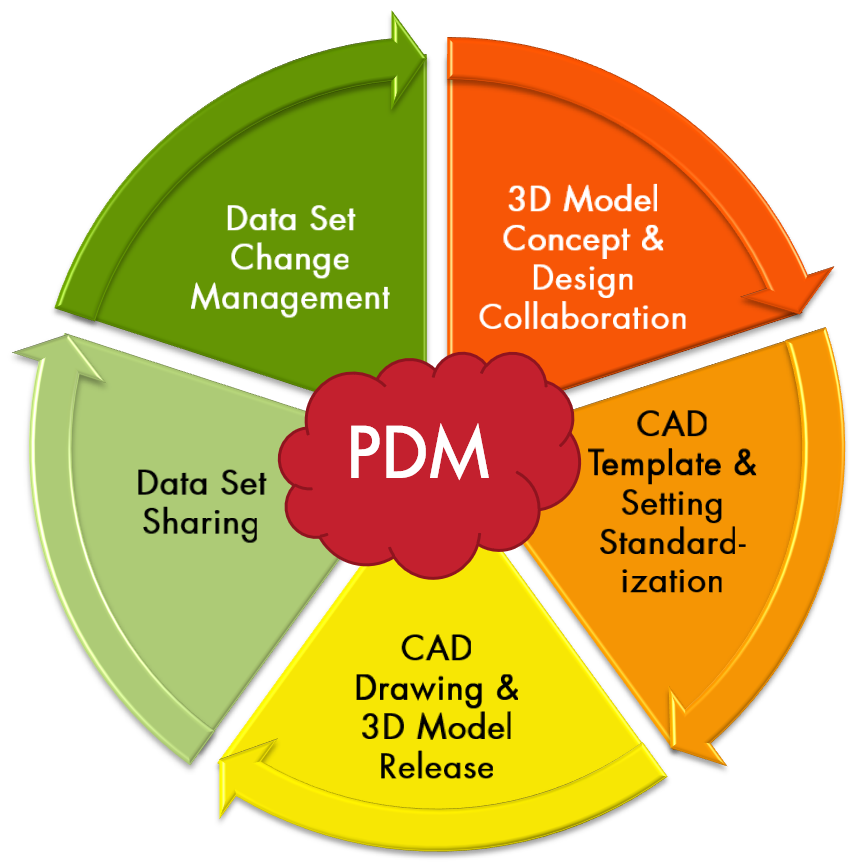

| Product Data Management Activities | PDM Activities |

|

| Activities that interrelate product data. |

| A specific product definition data set that defines a particular stage of manufacturing and conformance to specification. |

|

[Primary] Any information that defines the physical or functional requirements of a product, to ensure design intent.

[Alt] The activity that defines a product. |

| An information system that stores record copies (44 U.S.C.3301) of product definition for their long-term archive and retrieval. |

| The record of transmittal and supporting procedures that authorize product definition for a lifecycle activity. |

| Denotes the totality of data elements required to completely define a product. Product definition data includes geometry, topology, relationships, tolerances, attributes, and features necessary to completely define a component part or an assembly of parts for the purpose of design, analysis, manufacture, test, and inspection. |

| A collection of one or more data file(s) that discloses, directly or by reference, by means of presentation (e.g., graphic or textual), representation (e.g., semantics or machine readable), or a combination of both, the physical or functional requirements of an item. |

| A unit of data for which the definition, identification, representation, and permissible values are specified (see Table 3-1). |

| An identified set of product definition that fully defines a product. |

| A system model that encapsulates a product. |

| Two-dimensional (2D) flat orthogonal representations of a 3 dimensional object; used to convey design, manufacturing and quality support information related to how an object is to be built, such as dimensions, tolerances, materials, construction notes and processes. Standardized by ASME Y14.5 and Y14.100. |

|

information about a product

Note 1 to entry: Note to entry: In ISO 10303, it is common to describe product information with respect to a specific industrial domain. |

| The product information model is an information model which provides an abstract description of facts, concepts and instructions about a product, such as a STEP Application reference model or STEP Application interpreted model. (cf NAS9300-003, 3.2.1) |

| The series of stages through which a product passes during its lifetime. |

| Data that pertains to the product lifecycle. |

| A system that manages as-built design information and is the authoritative source for the eBOM, changes, data package, design deviations, and usage. |  |

| Product Lifecycle Management Software | PLM Software |

|

| PLM software manages information throughout the entire product lifecycle from ideation, design and manufacture through service and disposal. |